Table of contents:

Internet of Things technology continues to conquer the world. Inventors are constantly coming up with ideas for new IoT-based solutions, some of which will forever change our lives, and some (such as medical ones) can even extend it. Businesses just taking their first steps in IoT need to plan their expenses properly and often tend to underestimate the budget for creating and scaling a new intelligence device. The 2Smart team shares their knowledge on this issue and helps to correctly assess how much does it cost to start a production of IoT devices today.

Place of the device in the architecture of the Internet of Things

The architecture of the Internet of Things today is described by several models, each of which implies a different number of layers. However, if we refer to the current recommendations of the International Telecommunication Union, then its reference model consists of four main layers of IoT:

- Application layer, which includes any applications the end user of the device utilizes for monitoring sensor data, interacting with connected devices, and configuring their settings.

- Service support and application support layer, which is a cloud or local infrastructure for tracking, storing, and processing device sensor readings, that is, the Internet of Things platform.

- Network layer, which is a set of network protocols that devices use to communicate with each other and transmit data to the cloud.

- Device layer, which is an IoT device with sensors that have firmware and middleware installed that allows the device to interact with other devices and the IoT platform.

The IoT device functions only in conjunction with solutions that ensure its operation at other layers of this technology. At the same time, the ITU, in its recommendations, lists the remote management of IoT devices capabilities and security capabilities that must also be observed.

In practice today, the operation of the device at the three higher layers of the Internet of Things architecture is provided by IoT platforms. Businesses entering the IoT market do not need to invest in developing appropriate solutions. Of course, custom development of their own platform or automation system can be the road that an ambitious project with an unlimited budget will take. But still, for most companies, the right option is to turn to ready-made solutions, including those distributed under the white-label model.

When it comes to the cost to make a production of smart devices and bring them to market, then using IoT platforms means predictability. You can study the pricing of any such platform and then order a demo to get a reasonably accurate idea of how much it will cost to connect devices and support their functionality.

Collaboration with IoT platforms is also beneficial for business because the developers of such software can be aware of the growth problems that the company will face when scaling. Businesses will be able to learn about these non-obvious problems during the platform presentation, and the software itself usually already includes solutions to these problems and is ready for the upcoming challenges.

But as for the cost of developing the device, this is a more complicated issue. Let’s dive deeper into this process to understand what’s in store for you along the way and what costs of starting a production of IoT devices you need to be prepared for.

What it takes to develop and bring to market a custom IoT device and how much it costs

The most honest answer to the question how much does it cost to start a production of IoT devices is, “we can’t say for sure”. Obviously, too much depends on the project and its complexity. You can enter the market with a simple consumer device or plan to launch a solution designed to improve corporate IT infrastructure. The more complex the project, the more expenses must be incurred at all stages, from the formation of the idea and the design of the solution to the launch of mass production of IoT devices.

However, we can distinguish three groups of IoT devices production costs that are always fair and that you should consider when budgeting for bringing IoT products to market:

- Development costs

- Production costs

- Operational costs

Development costs

It doesn’t matter what kind of device you plan to bring to market, but you always need to develop software and hardware. It is generally accepted that in this pair, software development expenditures outweigh. Although software development costs less, the amount of software is larger, so the business incurs more costs for the work of programmers than for the work of embedded developers.

However, it should be borne in mind that the following solutions are included in software development:

- Device firmware.

- An application to control the device from a smartphone.

- Web application for device configuration and control.

- Custom backend business logic.

- Software for integration with specialized end-user software, if necessary.

- Software for production tests, if necessary.

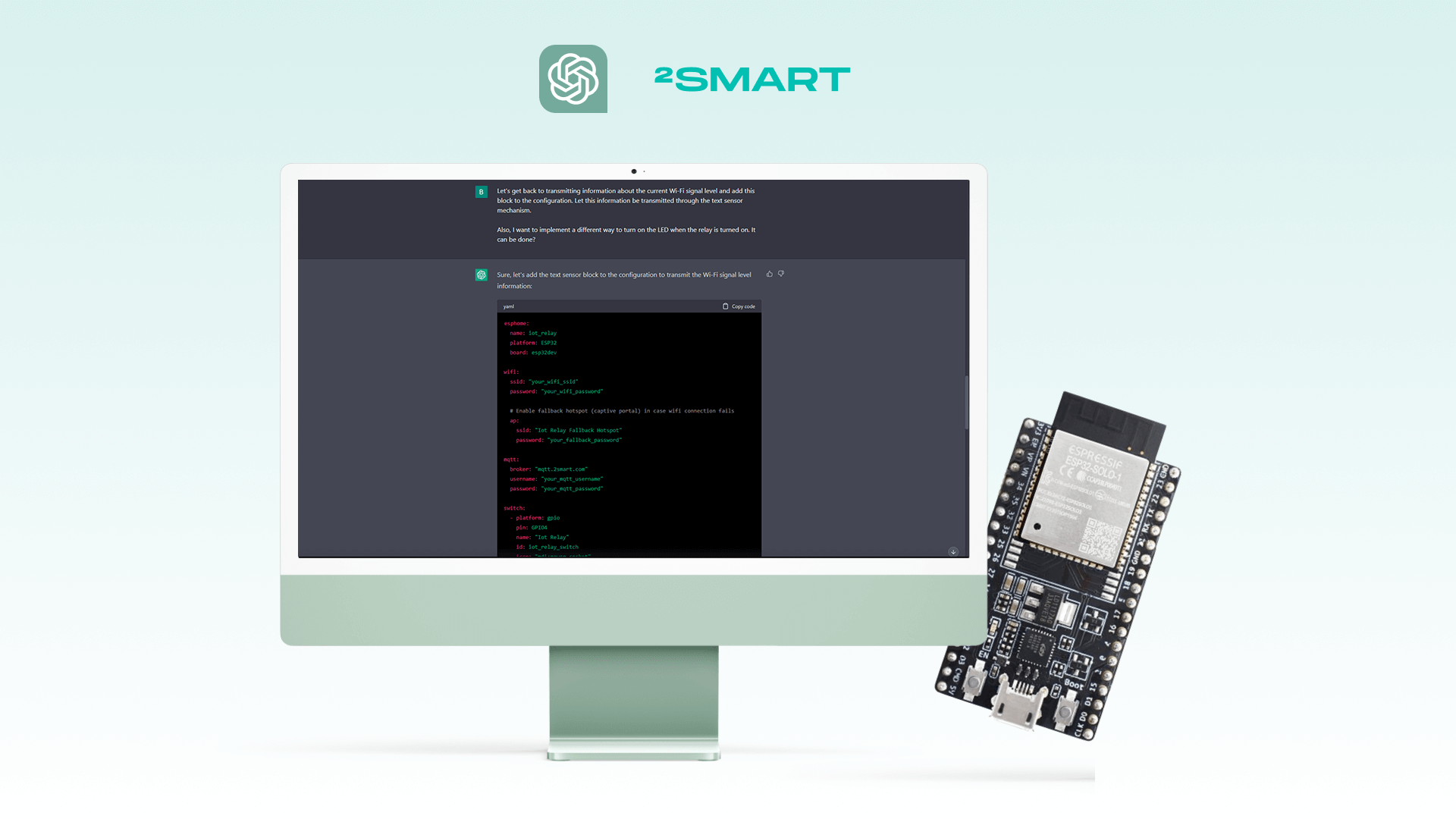

You need to know that the IoT platform can close most of these solutions if you use its services and do not develop your own. This means that development costs, in this case, can be lower and more predictable.

For example, in 2Smart, you can get a ready-made mobile application for managing your device, support for which is included in any standard platform tariff. If you are not embarrassed that the device’s end user will control it from the 2Smart Cloud app with the platform logo, the app development costs will be zero. If you opt for white labeling the app and branding it for you, you only need to incur the cost of customizing the app’s look, which is much lower than the cost of developing an app from scratch. In the second case, you won’t have to worry about app maintenance either, as it will be updated simultaneously as the native 2Smart Cloud app.

When talking about hardware development, we must keep in mind the four main stages of this process:

- Collecting the requirements & understanding goals. Your device idea can be quite abstract, so it’s essential to define precisely what the device will look like in practice. Define the concept of the product, write a detailed description of the project, research the market, and study competitors’ solutions. This will help you lay the foundation for your idea’s future success.

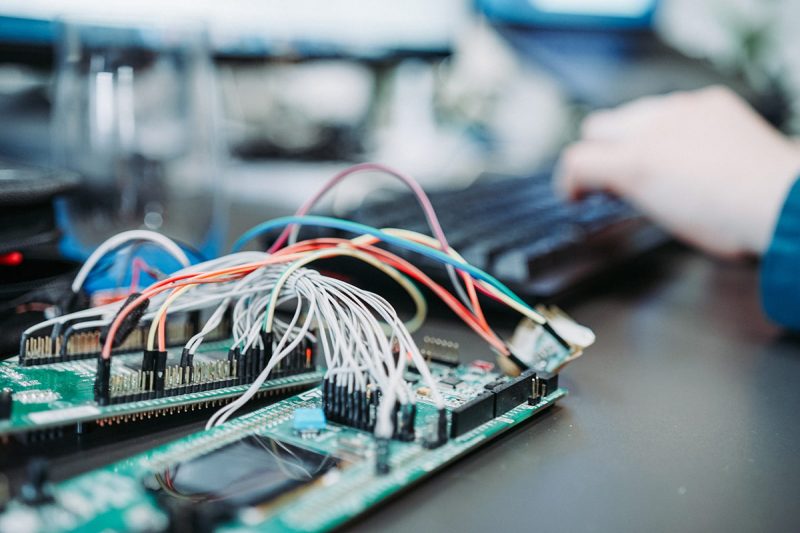

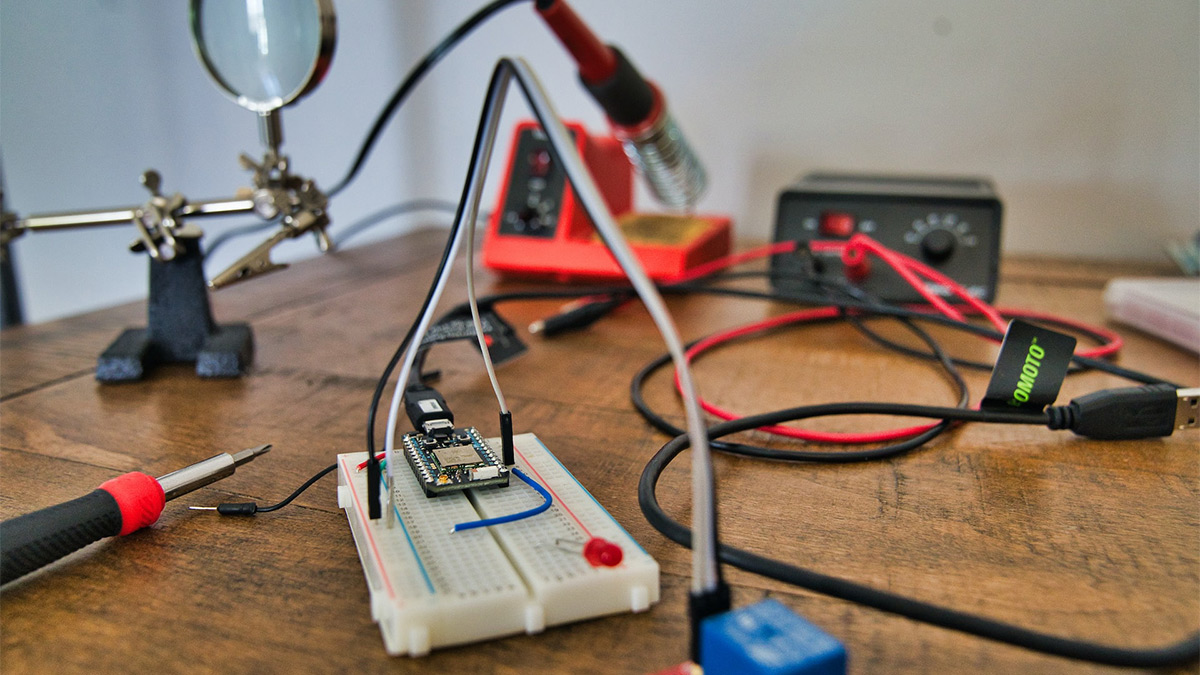

- Selecting the proper hardware. To begin with, try to assemble Proof of Concept, making the most of ready-made hardware solutions. Evaluate several solutions and choose the best one, considering its cost and quality.

- Choosing the proper tech stack. Test and select technologies, protocols, libraries, and firmware writing methods to meet your needs. Your goal at this stage is to decide on the tools you will use in a full-fledged product.

- Development & testing. Choose a development model and QA testing strategy. Set clear deadlines for each development phase, depending on its complexity and potential problems. You have to create several iterations of IoT product prototypes to get a ‘looks-like, works-like’ prototype eventually.

We have described all four steps above in more detail on the WebbyLab blog. If we talk about the overall costs, then they will be at least $4500-5000 but can be much higher for complex equipment.

Let’s collaborate

We’re empower your business with our technology expertise

Production costs

This type of expense becomes relevant once the development and prototyping of the device have been completed and the business is ready to start producing devices for sale.

In addition to the direct cost of production of IoT devices, this type of expense may include the cost of certification of your product, the cost of production testing, etc.

It is impossible to name the exact amount of such costs since it depends on the features of a particular device. However, we can highlight the following essential items of connected devices’ production costs:

- purchase of electronic components,

- production of printed circuit boards,

- production of plastic parts,

- assembly of devices

- testing and technical control,

- retail packaging and printing instruction,

- scrap rate,

- returns,

- delivery of devices from the factory to stores,

- taxes and duties.

Operational costs

IoT devices only perform their tasks when they are connected to the network. It can be both the public Internet and the local area networks of enterprise companies. Be that as it may, servers and software are needed to keep such equipment working.

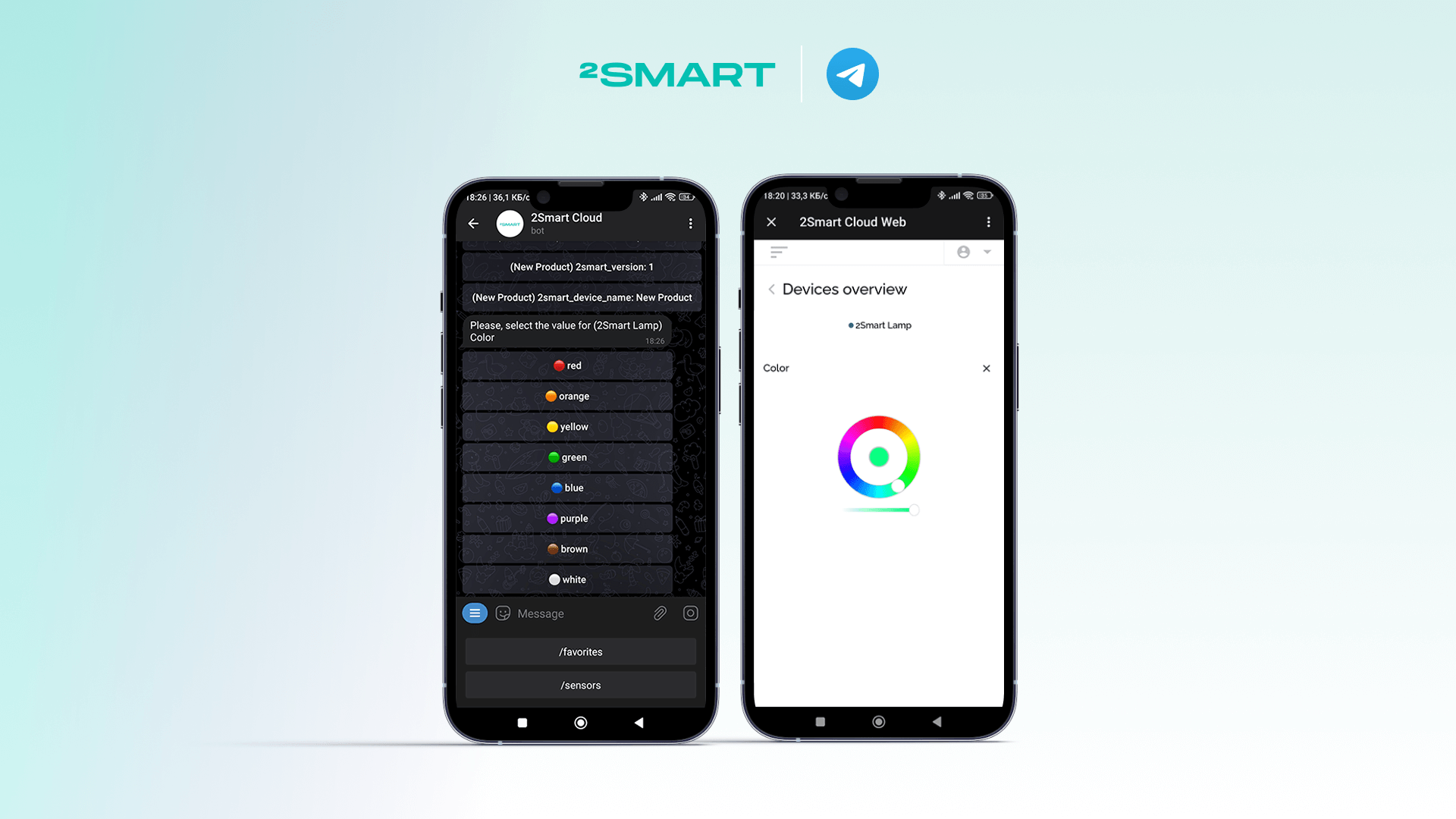

In fact, at this stage, we are dealing with the payment of the Internet of Things platform so we can calculate operational costs quite accurately and quickly. For example, if we look at the pricing of the 2Smart Cloud remote IoT device management platform, then supporting 200 devices will cost the business 49 euros per month. This is 24.5 euro cents per month or 2.94 euros per year for one device. The price of IoT platform services includes infrastructure and software support.

Based on such calculations, a business can easily determine how much will be the operational costs over the entire life cycle of the device. This amount can be included in the device’s price or the subscription cost, depending on which model the business plans to use to distribute its product.

Let us help you calculate the cost to start a production of smart devices

The 2Smart team has been involved in launching many IoT projects, from independently producing a small batch of consumer devices, such as the WOW Fire Lamp, to helping with deploying a business based on the operation of complex equipment, as in the MyBox project. You can contact us for help with calculating the cost of IoT devices production by sending your IoT project description to contact@2smart.com

FAQ

What factors contribute to the cost to make a production of IoT devices?

The cost to make a production of connected devices depends on several factors, including the complexity of the device’s design, the quality and quantity of components used, the manufacturing process employed, and the scale of smart devices production. Additionally, factors such as research and development costs, labor expenses, and regulatory compliance requirements can also influence the overall cost.

Are there any cost variations between different types of IoT devices?

Yes, the production of smart devices cost can vary depending on the type of device. Simple IoT devices with basic functionality and limited features tend to be less expensive to produce compared to more complex devices with advanced sensors, connectivity options, or processing capabilities. The choice of wireless technologies, such as Wi-Fi, Bluetooth, or cellular connectivity, can also impact the manufacturing cost of IoT products.

How does the scale of production affect the cost of making IoT devices?

The scale of production has a significant impact on the cost of manufacturing IoT devices. Generally, larger IoT device production volumes allow for economies of scale, reducing the per-unit manufacturing cost. Higher production quantities enable manufacturers to negotiate better deals with suppliers, optimize manufacturing processes, and invest in specialized equipment, ultimately driving down the overall connected devices production cost.

How to do IoT cost estimate correctly

To make a correct IoT cost estimation, it is essential to define the project scope, identify the necessary components and technologies, research their costs, consider development efforts, factor in manufacturing expenses, account for testing and certification, include post-production costs, allocate a contingency budget, regularly review and refine the estimate, and seek expert advice when needed. By following these steps and considering the specific requirements of your IoT project, you can create a more accurate cost estimate that helps with planning and budgeting.

Don't forget to share this post!

Read Next

Let’s dive into your case

Share with us your business idea and expectations about the software or additional services.