Table of contents:

If you are considering starting a consumer IoT device business, you are probably worried about many details rarely covered on the web. How to properly organize the process, what you need to remember from the very beginning so that later you don’t have to redo the work again. The 2Smart team has some experience developing and launching IoT devices on the market and is ready to share it in this article.

Stages of Developing and Bringing a Consumer Smart Device to Market and What to Tackle First

Although the main product of the 2Smart team is software for connecting and supporting IoT devices, we have implemented several projects in which we have developed consumer devices from scratch and brought them to the market. Among other things, it was essential for us to gain such experience to understand the needs of our customers better, improve our main product using this knowledge, and help customers build their business processes correctly if they request such expertise.

The devices we have developed and brought to the market are, first of all, the Propuskator controller line for remote control of electric locks and gate or barrier drives, as well as the WOW Fire Lamp – a smart light fixture with many effects.

The main life hack we want to share based on our experience is to follow the steps below but never get stuck on the current one. You need to always keep in mind what lies ahead for you to take into account certain nuances in advance. This approach will save you time, effort, and money and will save you from redoing work.

Here is a list of the main stages of your path to success in the smart device market:

- hardware development,

- hardware manufacturing,

- case design and manufacturing,

- certification,

- device packaging design,

- preparation and printing of instructions,

- after-sales device maintenance and support.

So let’s dive deeper into each of these seven steps to your future success.

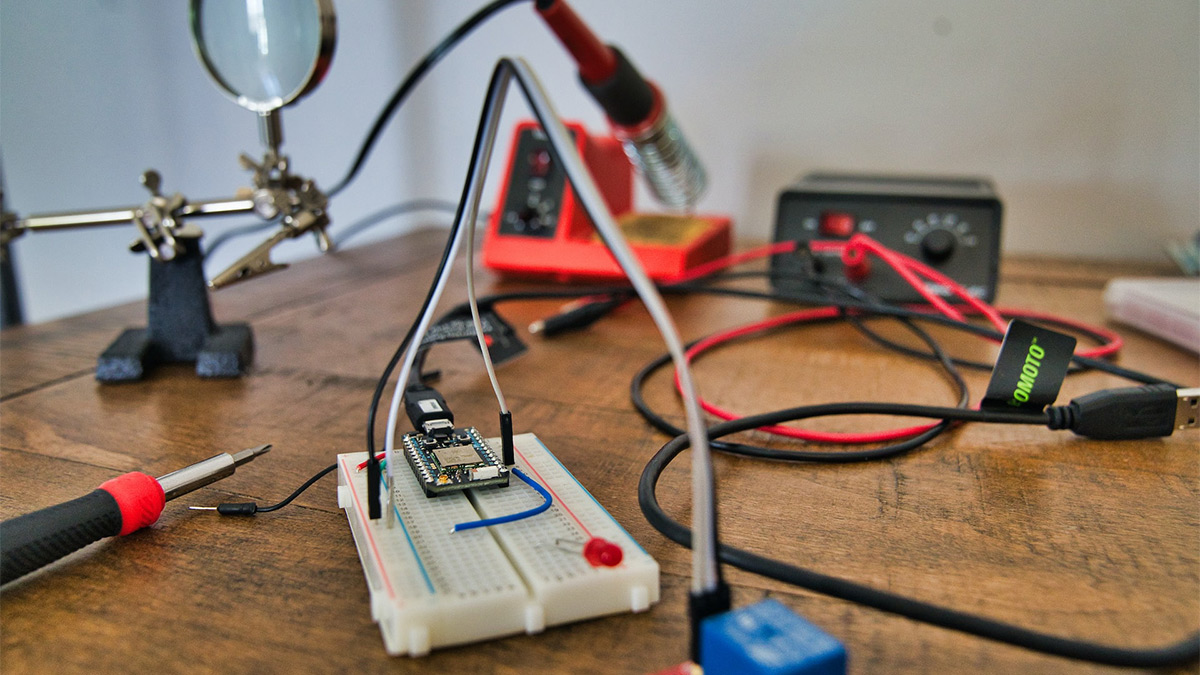

Hardware development

Of course, this is the first thing you should start with. Hardware development is a long process that includes many iterations, from Proof of Concept to the ‘Looks-Like, Works-Like’ prototype. You can begin this work before you decide on the software, whether it is a cloud IoT platform like 2Smart Cloud or a white-label solution like 2Smart Business Platform.

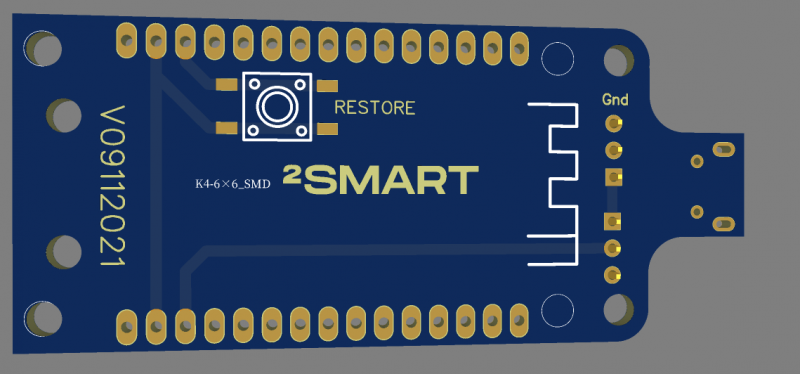

Hardware developers have a lot of work to do during this phase. They need to make a PCB design, and a schematic diagram, prepare all the materials for production, assemble a small pilot version of the devices, and check the hardware. This is followed by several iterations of bug fixes and product improvements until it meets all your requirements for the perfect device that will conquer the world.

When developing device prototypes, specialists can use the most unexpected solutions. For example, when our team worked on a security robot, even children’s Lego robotics kits were used in the early prototyping stages.

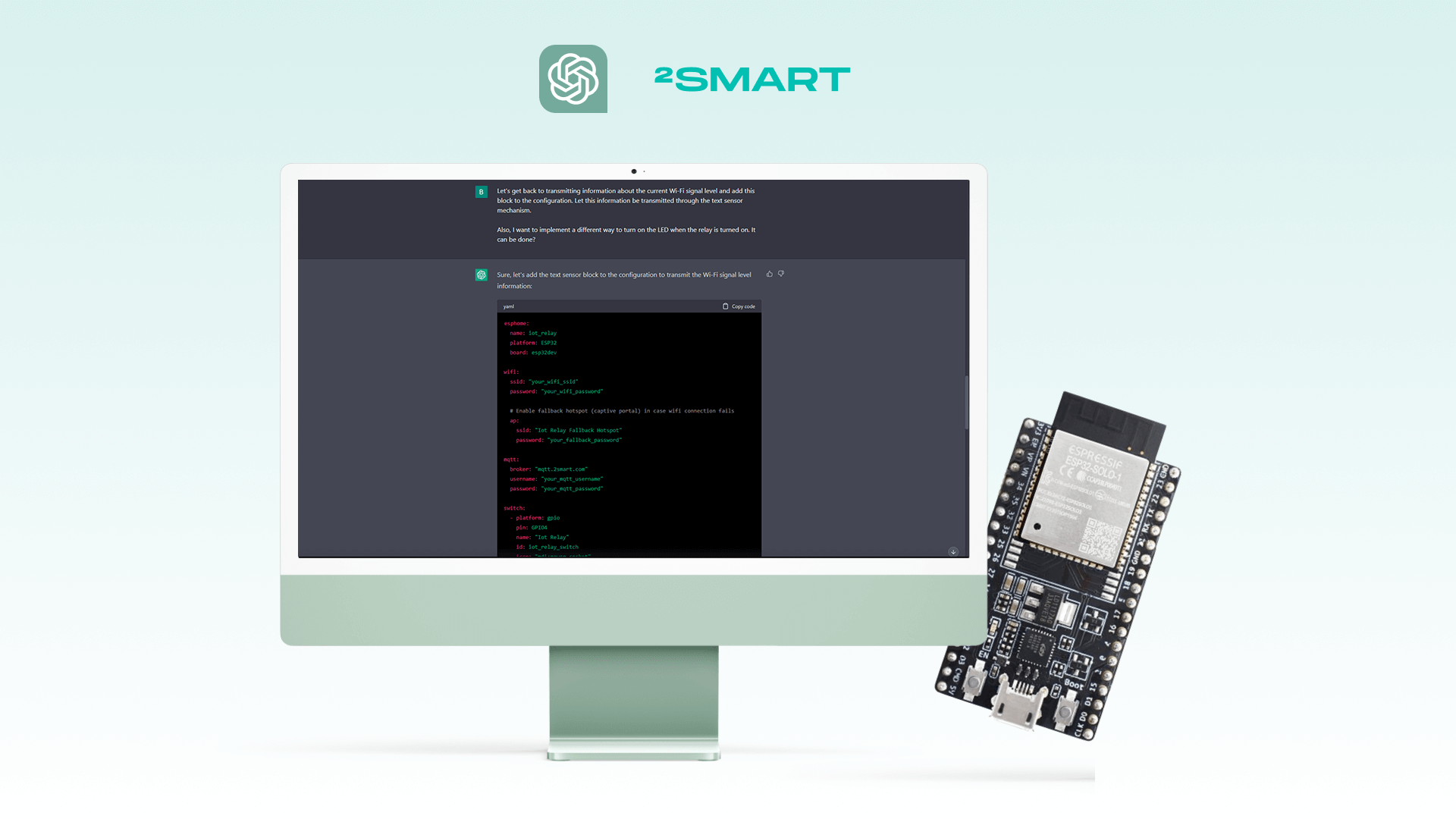

Usually, after the device has become perfect in terms of hardware, developers write a specification for it, and firmware developers get involved. And at this point, of course, you should already choose the software to turn your invention into a full-fledged Internet of Things product. The firmware should consider the IoT platform’s requirements – for example, to connect ESP32-based devices to 2Smart Cloud, there is an SDK prepared by our team. And for devices based on other microcontrollers, we wrote documentation.

Hardware manufacturing

The firmware must be installed on the entire batch of your product, and the easiest way to do this is to order the production of already flashed devices. Devices are often flashed at the factory, and installing the firmware on them yourself is instead an exception.

Thus, the lack of ready-made firmware can prevent the launch of production. Therefore, we advise you to keep this in mind at the hardware development stage and optimize the process of writing firmware. First of all, you need to pre-select the IoT platform that devices will connect to consider its requirements when writing firmware. Once a solution is chosen, firmware developers can work with hardware developers and connect prototypes to the IoT platform.

Case design and manufacturing

This step will require you to think long and hard and make a decision from several alternative approaches.

Without a doubt, the best option is the design and manufacture of a custom case. With the help of designers, you develop a project, produce several versions of a prototype case, test them, and make changes if needed. When testing a case design, you should also conduct marketing research to understand how the appearance and ergonomics of the device will appeal to future buyers of your product.

The option described above is the most correct, but it has one significant drawback: the high cost of designing and manufacturing a custom case. In addition to a long cycle of design and testing of the project, you will have to invest in the manufacture of molds and quality control of finished cases. Not every startup can afford this approach so you may consider cheaper alternatives.

The first of these alternatives is ready-made cases that will fit your product. The disadvantage of this solution is that you will most likely need to adapt the PCB design to fit the interior of such a case. Therefore, it is advisable to decide on the use of a ready-made case even before the hardware development stage so that developers take into account its features.

Another alternative is generic cases, which will most likely not be very suitable for the size of the hardware you have already developed, but in which this hardware can still be placed. If you are going to produce a sufficiently large batch of devices, then it will make sense for you to order the manufacture of such cases under your brand using the OEM model. Generic cases can be plastic, metal, or anything else, and you will undoubtedly have a wide choice.

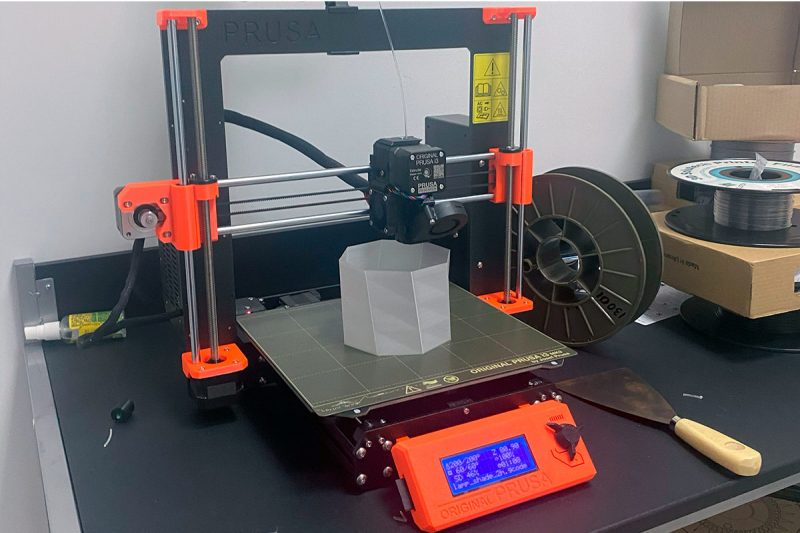

Finally, another alternative that will suit you if you are going to produce small batches of devices at the start is the independent production of cases. You will need to purchase your own 3D printer and print the cases yourself, or you can order 3D printing. We used this option to make cases for the Propuskator controllers and smart lamps. Producing on a 3D printer is a good compromise that combines the advantages of custom case design and cheap manufacturing.

By the way, self-production can be a good solution, including for those businesses that plan to order mass production of custom cases in factories. This way of manufacturing cases is an excellent option at the stages of testing device prototypes, when launching a pilot batch, etc. Based on the results of technical and marketing testing, a business can quickly make changes to the case design, achieve the ideal, and only after that order the production of perfect cases at the factory.

Certification

The fourth stage on our list, which follows the production of finished hardware and the case, is certification. However, you can make a big mistake if you think about certification only after you launch mass-production devices. Knowing everything about certification is necessary at the earliest stages of designing an IoT product.

Certification is a very specific process that depends on the region where the devices are used. You need to study local regulators’ requirements and consider them already when designing hardware and case. Otherwise, you may find yourself forced to make significant changes to an already developed device and incur losses.

Let’s collaborate

We’re empower your business with our technology expertise

Device packaging design

From a marketing point of view, how the device box looks is very important. At the first acquaintance with your product, the user evaluates it through the eyes. It is essential that a consumer smart product not only has a pleasant appearance but is also packaged in a high-quality modern package. You can emphasize the features of your product with its packaging. For some devices, a bright box is suitable; for others, a craft eco-friendly packaging; for others, a durable, robust case.

In addition to the box itself, various inserts, stickers, and similar accompanying materials, including instructions, matter. We’ll talk more about this below.

Speaking about the experience of the 2Smart team, we ordered custom cardboard boxes with branding for the Propuskator controllers and accompanied the device with inserts with helpful information.

The final version of the box for the WOW Fire Lamp was generic plywood boxes of suitable size, inside which the lamps were placed in soft shavings. We shipped the first devices in cardboard boxes without shavings inside, and, unfortunately, some lamp cases were damaged in transit. Transportation conditions should also be considered, and robust packaging should be provided for fragile devices not to upset the user.

Based on our experience, we also advise you to pay attention to the complete set of devices. We believe it is essential that the product be as complete as possible. For example, if the devices are powered by batteries, the batteries must be included. And if for some reason you do not put batteries in, you need to write in a conspicuous place that the user needs to buy them on their own. Otherwise, the buyer will be frustrated when they cannot immediately start the device by bringing it home.

Sometimes related equipment is not included in the package. For example, we do not include a power supply to the Propuskator controllers since the customer’s access control system is often already equipped with it. But a high-quality power supply and a USB cable are mandatory for smart lamps since the device requires a stable power supply for the LEDs to reveal their capabilities. Therefore, we decided to select the power supply and cable and supplement the lamps with proven components.

Preparation and printing of instructions

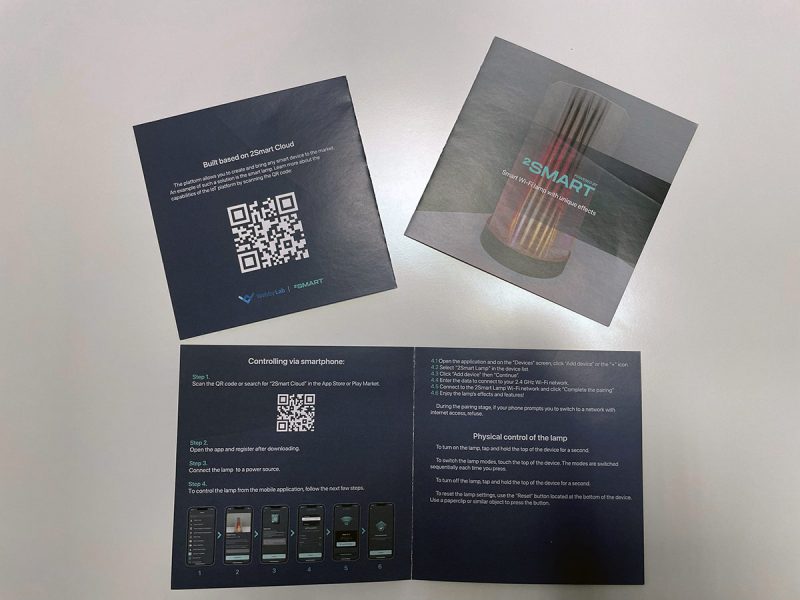

Instructions and other printed materials are also important in marketing and demonstrating your concern for the end user, especially if we’re talking about IoT devices, which can be a little tricky for the untrained user.

The manual for the device should preferably be illustrated and describe how to connect the device, pair it with a mobile application, resolve possible technical issues, contact support, etc. Such information should be placed on paper instructions, your company’s website, mobile app, social media, etc. You can place a link to your website and social media in the instructions, packaging, and even the device’s body in text and the QR code format.

You can come up with your own unique features or copy the marketing solutions of prominent manufacturers, supplementing the accompanying materials with colorful stickers and other materials that will eventually advertise your product offline by users themselves.

Of course, preparing instructions and other materials fall entirely on you. However, the 2Smart Cloud IoT platform can help you to some extent – pay attention to our built-in functionality for generating QR codes for pairing devices. Generate a QR code in seconds and add it to a manual or print it as a sticker so the end user can quickly pair the device with their smartphone.

Device maintenance and support

IoT devices continue to improve even after the end user gets them. You will most likely update the firmware and fix its bugs, and devices will receive these updates over the air. You will probably improve the design of the mobile app to manage your product.

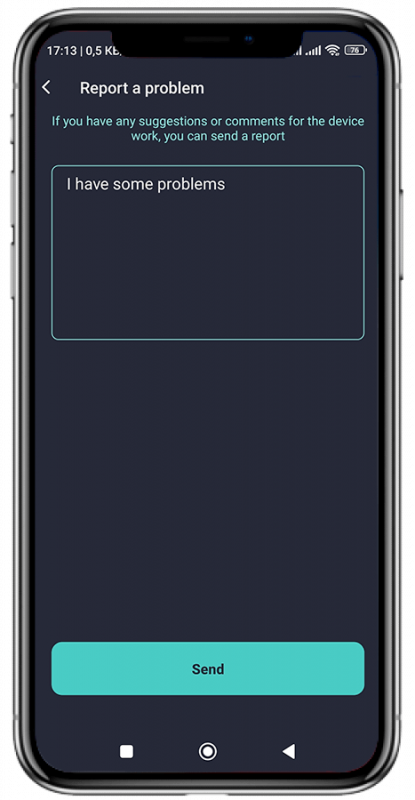

In addition, you need to organize the work of a technical support team that will respond to online user requests, help them with troubleshooting, and possibly even go to the user to fix serious problems.

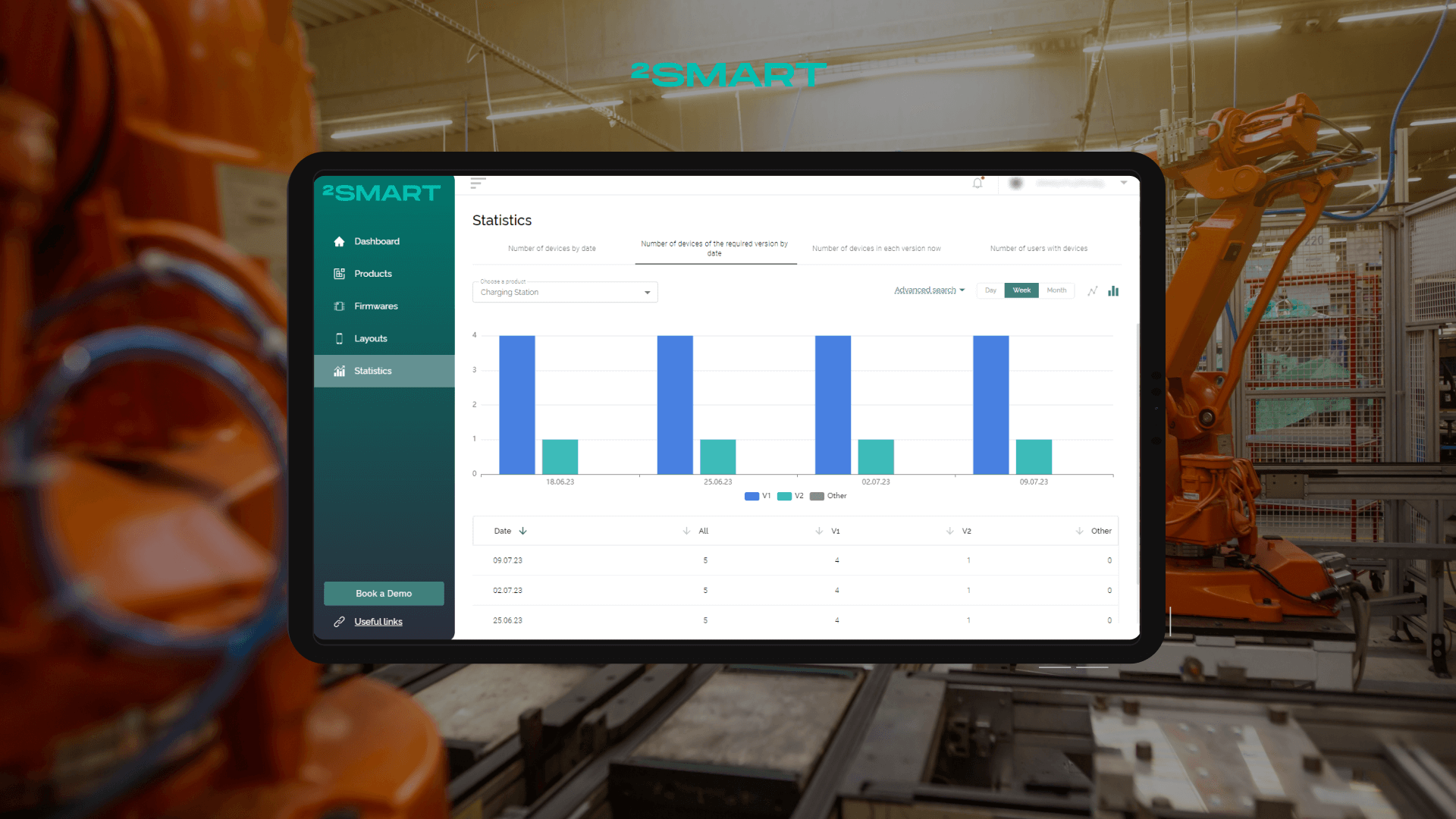

When using 2Smart, you also get tools to help you through this step. Our IoT monitoring system allows you to control the status of your fleet of devices. To deliver firmware updates over the air to an entire batch of devices, you just need to upload the updated firmware file to the cloud and publish the product changes. The devices will download the updated firmware according to their settings.

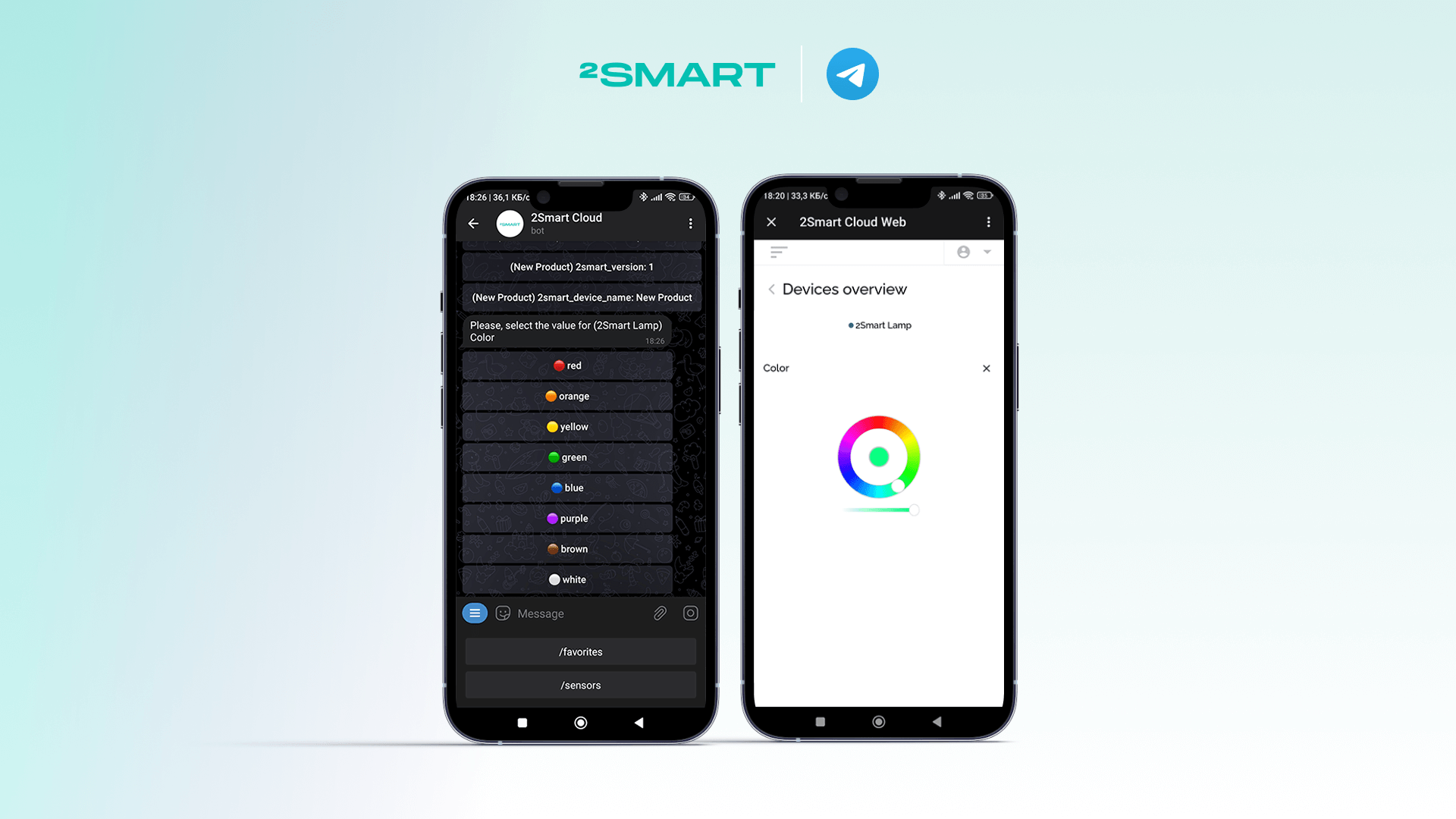

To update the design of a mobile app for device control, you just need to customize it in a new way in the no-code builder using widgets and publish the changes, after which users will see the app’s new look even without updating it. If something happens to the device, users of the 2Smart Cloud mobile application and its white-label modifications can write to support directly from their smartphone.

Of course, you must also provide for the terms of the guarantee, exchange, or return of the goods in advance. As with the certification stage, you must focus on local consumer protection legislation.

Build Your Business With 2Smart

We hope that our experience has been helpful to you and that you can build on it to start an IoT business, avoiding a number of mistakes along the way. If you have any questions, you can contact us and book a meeting with experts by writing to contact@2smart.com

We believe that the Internet of Things will continue to transform our world; therefore, we root for every new startup that takes its first steps in this technology. Consequently, we have tried to develop a pricing policy that is as loyal to young businesses as possible. You can use our power for free or a low monthly subscription so that the costs of the IoT platform do not exceed your capabilities. Join us!

Don't forget to share this post!

Read Next

Let’s dive into your case

Share with us your business idea and expectations about the software or additional services.