Table of contents:

In this article, the 2Smart team talks about all the stages of building a new IoT solution and also shares its own approach and experience in effectively creating and bringing new devices to the market.

Stage 1: Formation of a Product Idea

Whether a new consumer smart home device or a cutting-edge industrial IoT solution, it all starts with an idea. The best ideas are born from personal experience when the inventor is faced with a particular problem and does not find a ready-made good solution. Dropbox was born because Drew Houston forgot to take a flash drive with the files he needed on a trip. This is a classic example of how successful ideas are born in the market.

At this stage, you must determine what fundamental problem your product will solve and formulate its general concept.

A case study from 2Smart

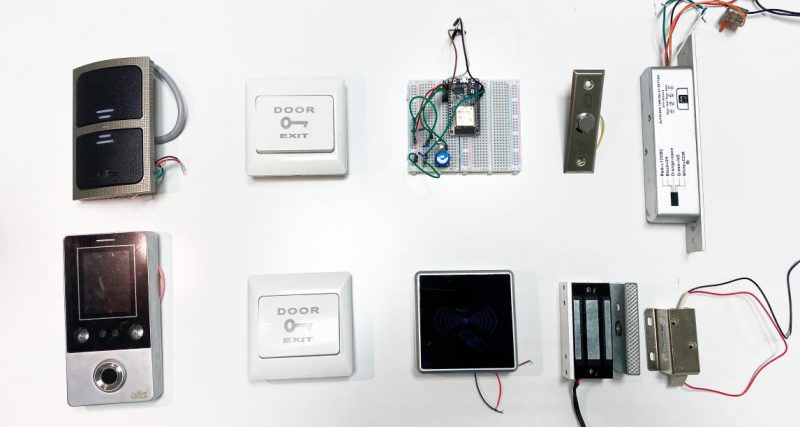

The experience of the 2Smart team, among other things, includes developing a cloud-based access control system and IoT controllers for it, which are produced under the Propuskator brand. The idea for this access control system came to the mind of our friend and investor, who needed an access control system for the cottage community in which he lives. Having discovered that the ACS and controllers on the market were not modern enough and did not meet his requirements, he formulated the idea of a cloud controller and ACS and came to us with it.

Stage 2: Market Research

After forming an idea for a new IoT product, you need to conduct market research to understand whether someone has managed to come up with and implement a solution similar to yours before you. When performing this research, several forks will arise before you, during which you will need to draw the correct conclusions and make the proper decisions. This will be achieved by carefully collecting and analyzing information with the involvement of business analysts.

If your idea is unique

If there are not and never have been solutions on the market that are similar to what you came up with, you probably need to quickly get a patent for your invention and start implementing the idea. Perhaps you have invented something that will make you a leader in the market and one who sets trends in an entire niche, as Apple does in the market of smartphones and accessories.

On the other hand, you need to make sure that your idea is relevant and interesting to the market. Perhaps it occurred to someone a thousand times but was not implemented simply because it has no prospects. To figure this out, you need to organize additional research to collect feedback from the market to understand whether there is a demand for your idea.

If your idea has already been implemented

If, during market research, you discover that someone has already offered the world something similar to what you came up with, there is no need to give up. Study your future competitors, identify the weaknesses of their solutions, and think about where your product can be better.

The most obvious ways to get to know your competitors’ products are by downloading and reading instructions and other documentation for their devices, reading reviews from real users, and purchasing a device for personal testing.

Based on the results of a careful study of competitors’ products, try to formulate your own unique selling proposition, which could be price, availability, reliability, user experience, expanding the range of tasks solved, etc.

Of course, when researching competitors, consider the size and capabilities of the company you will be competing with. Suppose you’ve devised the idea for a smart thermostat and discovered that Google is releasing a similar device called Nest. In that case, it’s wise to give up trying to compete with such a giant, especially if you can’t offer a unique selling proposition that will cause a wow effect among users.

Whether someone has brought your idea to life before you or you are a pioneer, the ultimate goal of the market research phase is to gain a deep understanding of your IoT niche. Moreover, we advise you never to stop and continue to monitor the current state of your niche since trends, technologies, and audience needs are changing very quickly today.

A case study from 2Smart

Obviously, access control systems and devices for controlling electric locks or gate drives are not something new on the market. Rather, on the contrary, this phenomenon has existed for decades, and this niche is quite conservative.

2Smart business analysts studied the access control systems on the market, purchased various access devices, and conducted interviews with experts in this field and real users. As a result, they identified the following shortcomings of the systems on the market:

- the need to install on a local server (additional costs for equipment, installation, and configuration);

- the need to involve third-party contractors for the installation and maintenance of the system;

- outdated, overloaded interfaces;

- additional training is needed to use the system.

The discovered shortcomings of the controllers are the following:

- complex installation due to large dimensions;

- lack of wireless connection to the network;

- the price.

As a result of market research, we formulated the following requirements, which include the USP of the new product:

- design a compact controller using the technology “Plug and Play” to control electric locks and automation drives;

- develop a cloud IoT access management system with the ability to operate on isolated servers;

- develop a web interface for configuring a cloud IoT access control system;

- provide the possibility of scaling.

Stage 3: Discovery

After you have analyzed your future competitors and formulated the USP of your product, it is time to plan to bring the idea to life. We recommend that you create a Business Requirements Document (BRD), which contains a complete list of features of your solution, functional and non-functional requirements, and other product components. By writing a BRD, you can highlight the list of competencies that you will need. And this, in turn, will allow you to understand what specialists you will need in your team and what work can be outsourced to someone else.

Thus, at this stage, you need to understand what market niche you are entering, how many employees your team needs, and what competencies they should have. With this understanding, you can make an assessment and begin organizing the work.

A case study from 2Smart

Having conducted market research and realizing that the new modern access control system has good potential and that we are ready to compete with current players in the market, we identified our USP and compiled a BRD. Next, we needed to understand the scale of the work ahead, for which we determined a scope of work and described what stages we needed to go through to create this product.

Here’s what’s on the list:

- The need to understand the subject area. ACS controllers are not independent devices but interact with controlled (locks, gate, or barrier drives) and control (exit buttons, tag readers) devices. So we needed a subject matter expert to tell us all the specifics. It is desirable that this specialist has practical experience in this area and understands the shortcomings of existing solutions, and ideally, knows what needs to be done to make the new solution better than the existing ones.

- Gathering a PCB development team, that is electrical engineers, who will develop the controller board.

- Embedded firmware engineer for developing device firmware.

- Gathering a software development team. The access control system must include a cloud backend, to which controllers are connected, and a web application for system administration. Also, according to our idea, the end user gets a mobile application to manage the available controllers.

- A specialist in developing a device case or a person who will offer a ready-made solution.

- A specialist in certifying such devices in different jurisdictions who will explain whether devices need to be certified to enter a particular local market and how to do it.

- The need to decide on the way to organize the production of controllers. Production can be transferred entirely to some contractor, or you can order the production of printed circuit boards, buy the necessary components, and assemble the controllers on your own.

- Quality control organization. The team should include a tester who knows all the intricacies of the device and can check the manufactured devices before they are sold or sent for installation to the customer. The engineering team should draw up a checklist to check all potential problem areas, which will help the tester not overlook anything and ensure that each instance of the device functions correctly, all components are working, the firmware is installed correctly, etc.

- Taking care of the consumer. Today’s market dictates an approach in which the manufacturer must provide end users of any product with positive emotions from interacting with it. In our case, the ACS controllers must be placed in high-quality packaging, inside which it also makes sense to put an inexpensive installation tool. The included instructions should be clear and should assist the user in installation. In addition, we have posted text and video instructions on the Propuskator website. Since IoT devices are not only about the devices themselves but also about their integration, the manufacturer must help the user as much as possible at this difficult stage.

Let’s collaborate

We’re empower your business with our technology expertise

Stage 4: Development and delivery

Developing an IoT solution involves iterative prototyping as the product becomes more and more similar to how it will end up in the hands of the end user. With the classic approach, there are several prototyping stages – from Proof of Concept to Engineering Prototype.

Based on our experience, we recommend taking an approach with Minimum Viable Product (MVP) building. Create a list of primary tasks, build an MVP, and with 20% of your efforts and resources, you can solve 80% of the problems facing you. By releasing an MVP relatively quickly and inexpensively, you can immediately begin testing it on the market and collecting feedback. Minimum Viable Product will help you understand whether there is a real market need for your solution, whether it meets the needs of your future users, and what adjustments you need to make to the project.

These are the tasks that Minimum Viable Product solves:

- Product viability check.

- Save money on solution development by focusing only on core functionality.

- Acceleration of product delivery.

- Initial customer research.

- Minimize risks in advance thanks to the ability to easily change the product strategy after testing the MVP on the market.

- The ability to formulate a suitable business model based on the identified strengths and weaknesses of the solution.

When talking about the process of building an IoT prototype, you need to keep in mind that any prototype consists of three components:

- hardware – the physical components that make up the device,

- firmware – built-in software on a device that performs certain functions,

- software – programs for managing, monitoring, and analyzing the device and the data transmitted by it.

Sometimes, a prototype can get by without software. In this case, device testing is carried out in headless mode, or engineers prescribe a minimum set of necessary control and data collection functions into the firmware and use the web interface.

Already at the prototyping stage, think about the typical IoT tasks that you will have to solve in any case:

- a well-thought-out pairing and discovery procedure to make it easy and convenient for people to connect a device,

- collecting historical data for subsequent analysis,

- convenient and thoughtful remote control features,

- OTA updating mechanism,

- notifications mechanism

- backup and recovery mechanism.

Key steps in building an MVP

The MVP building process consists of three main steps:

- Selecting suitable equipment.

- Choosing the right technology stack.

- Development and testing.

Let’s talk more about each of them.

Selecting suitable equipment

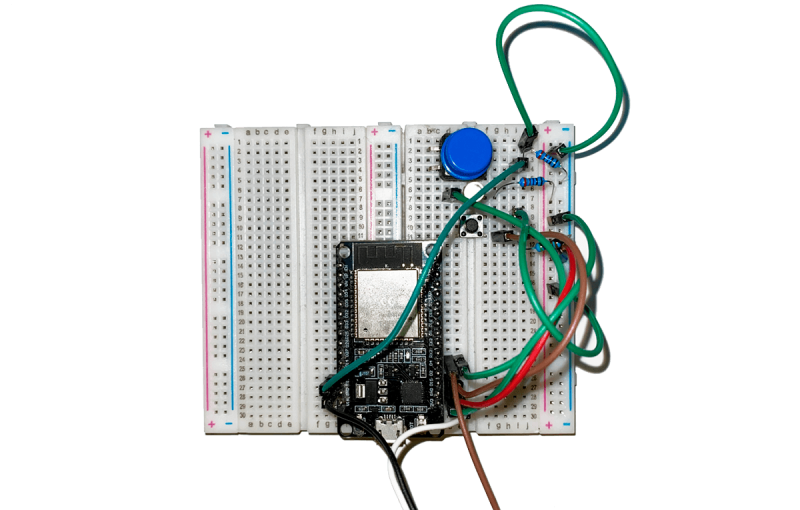

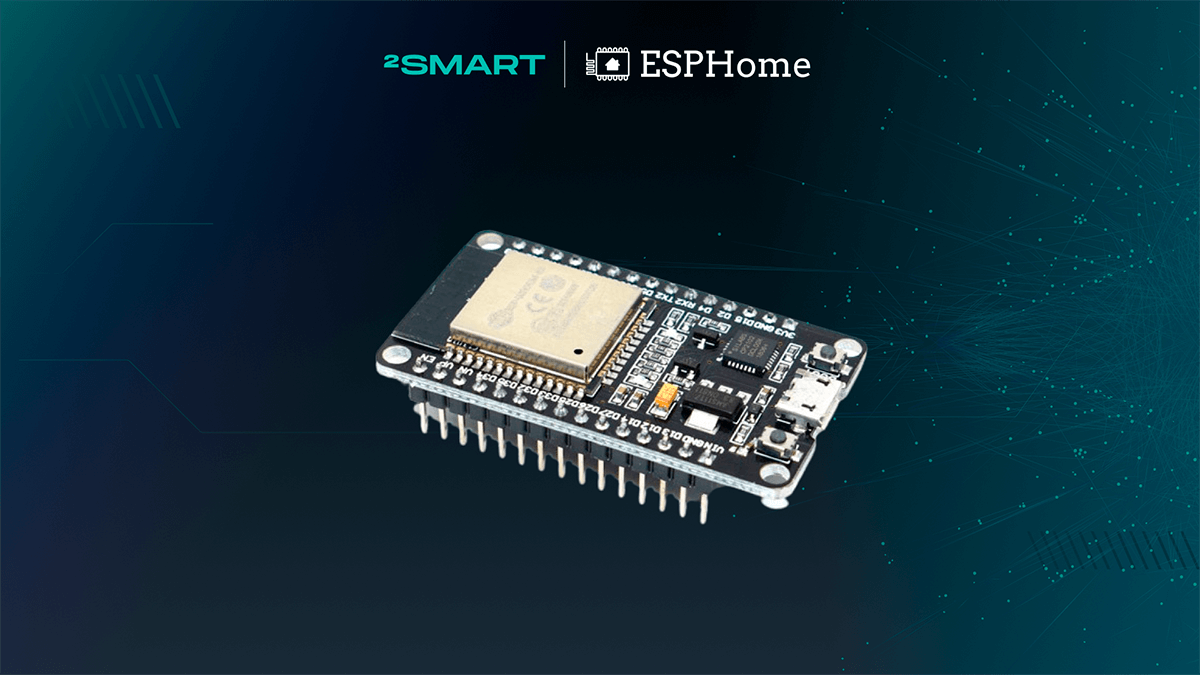

Understanding the goals and requirements for a new device, developers usually start with a Proof of Concept (PoC) build. This is the name given to the very first prototype, which is based on ready-made hardware solutions and is aimed at testing the product hypothesis.

When putting together a PoC, it’s a good idea to evaluate several solutions and choose the one that works best in terms of quality and cost. It is also essential to check the firmware’s compatibility with the selected equipment.

We recommend that, whenever possible, you build a PoC using off-the-shelf solutions instead of building a prototype manually by soldering or using a breadboard. Depending on the type of project, equip your PoC with the necessary sensors and IoT devices.

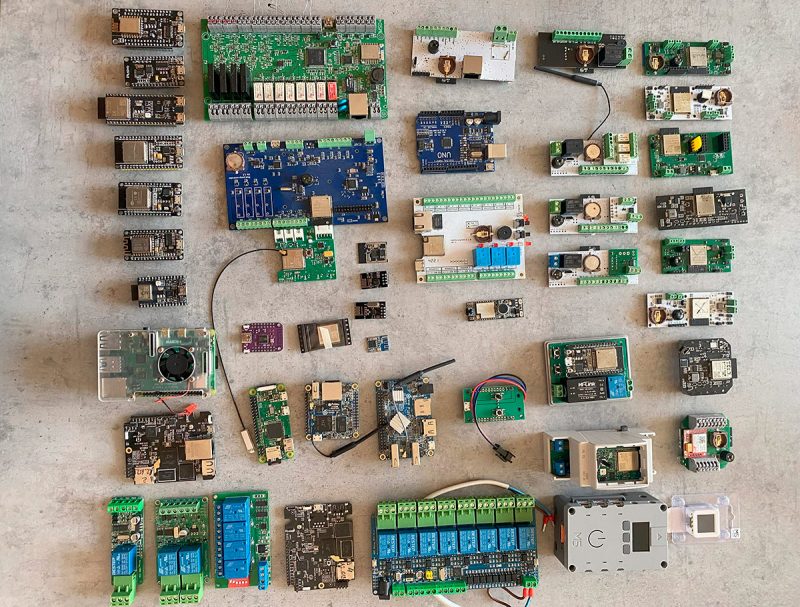

Here is a list of typical hardware components for an IoT solution that you will need to decide on:

- Sensors that collect data necessary to solve the tasks assigned to the device.

- Microcontroller for processing collected data and controlling the device.

- Actuators that perform specific actions when receiving commands from the microcontroller.

- Connectivity solutions (Wi-Fi, Bluetooth, cellular, etc.) that will ensure uninterrupted data transmission for the operation of the IoT solution.

Choosing the right technology stack

The essence of this stage is testing and selecting technologies, protocols, libraries, and methods for writing firmware to solve specific problems. You need to decide on the tools you can use later when creating a full-fledged product.

If your team already has experience building new IoT solutions similar to the one you are currently developing, you can skip this step. Most likely, you already know which technology stack you will use.

Development and testing

We recommend that you create a development plan in advance, setting deadlines for each stage, considering its complexity and potential problems that may arise during implementation. Be sure to write down a product quality testing strategy and a plan to eliminate risks and issues.

The more prototype iterations it is possible to make, the better. It is advisable to test each iteration, make changes, adjust it, transfer it to a group of uninterested users for testing, collect feedback, correct the firmware, and make a new iteration. This allows you to make the final product of the highest possible quality.

Customer experience is what you need to rely on throughout the entire new product development cycle. During the MVP testing stages, you should interact as much as possible with ordinary users, whose feedback will give you invaluable information and can push you toward those improvements that will become the killer features of your solution.

Large production should be launched only when you are confident in the device, and the quality of the firmware, when you have all the accompanying materials, and are ready to begin sales as soon as the devices are manufactured immediately. Try to avoid a situation where the finished product sits idle in warehouses because the more time the devices are stored in this way, the more likely you will desire to improve something further, a new firmware version will appear, etc.

A case study from 2Smart

While developing the Propuskator ACS, we quickly launched an MVP, which helped us identify the weaknesses of the original project and find a new niche for IoT access controllers.

Having decided on the technology stack and chosen the basis for the hardware, we launched parallel development of the printed circuit board, firmware, and device design to speed up the process. Since different team members handle these processes, this approach is most appropriate. Of course, team coordination matters when the firmware developers know which chip the PCB developers chose and the case designers know the dimensions of the future board and other components of the device.

The first ACS distributor was an investor who ordered us to develop the system. Thanks to the ability to test the product on a small group of users, we received feedback from real consumers and requests for additional functionality. This helped us plan further development of the solution. In particular, we added the following to the project:

- Expanding the range of controllers due to the possibility of connecting via Wi-Fi, GSM, Ethernet, and RS-485.

- A universal interface for connecting the reader to the controller to ensure compatibility with almost all modern readers.

- Possibility of connecting opening sensors, security systems, and protection against incorrect power connections.

- Special housings and mounting accessories for installing the device on a DIN rail.

- Expanding of the range of controllers due to devices equipped with relays for controlling drives via dry contacts. Initially, we only developed versions capable of operating locks using power.

- Improvement of the controller firmware by adding numerous settings to facilitate compatibility with various equipment and operating modes.

- Improvement of the ACS software to eliminate a number of deficiencies identified during the testing phase and integrate new peripheral equipment.

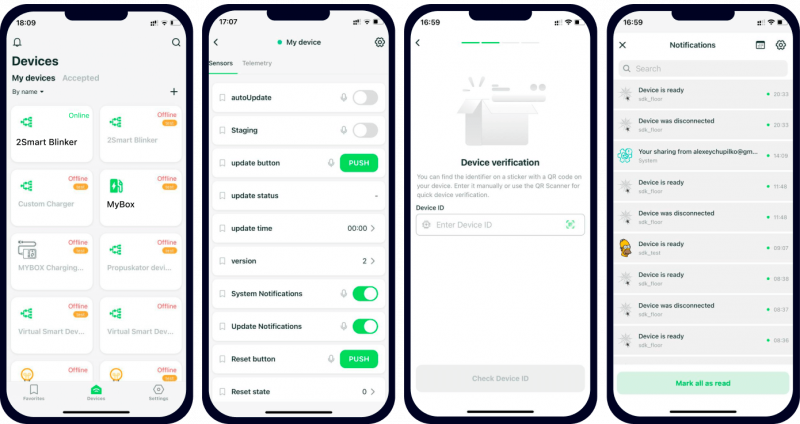

- Improvement of the functionality of the mobile application by adding new methods of pairing, access control, and support for multiple ACS accounts.

Stage 5: Launch

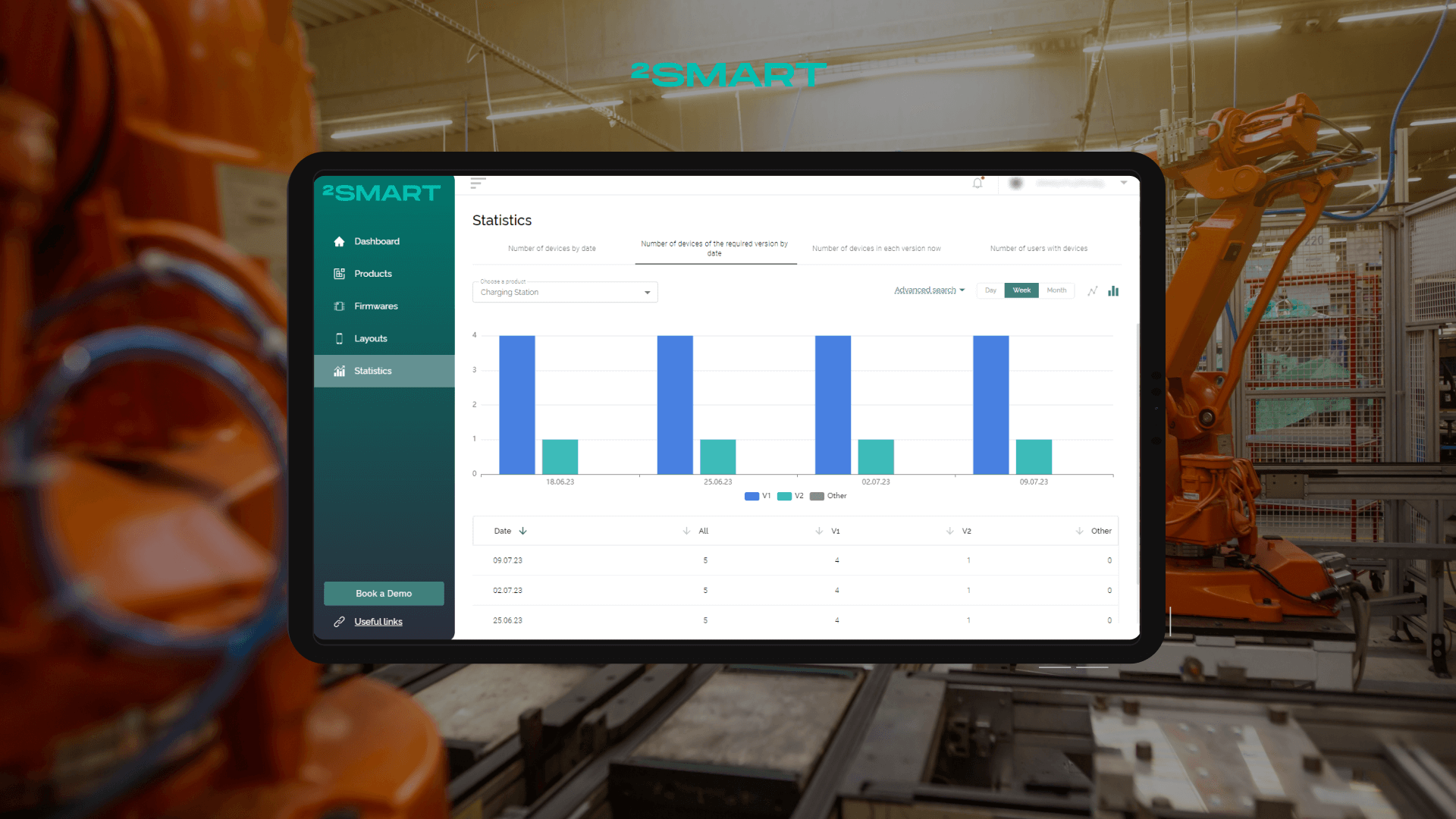

When preparing for launch, we recommend that your product include as many user analytics capabilities and collection of business metrics as possible. This will help you analyze user behavior and device performance, giving you information you can use to improve your product.

The critical components of this stage are the following:

- Choosing the best manufacturer. You need to find a supplier who has sufficient competence, experience, working capacity, and transparent communication.

- Participation in the production of your IoT solution. You must be as involved as possible in the process to ensure that the final product meets your vision, requirements, and quality standards.

- Quality control. Monitor the quality control team and guide their efforts in the right direction.

Once the product is released, you need to organize a go-to-market process, where the critical components are the following:

- Development of a comprehensive marketing strategy to increase awareness and interest in your IoT product.

- Developing a sales and distribution strategy to ensure your solution is effectively delivered to customers.

- Providing resources and documentation to support customers in successfully implementing and using your IoT product.

- Coordination of the deployment of your IoT product across customer environments.

As your solution spreads, you will move into business-driven development, where the market and users begin to dictate to you what improvements they need. Keep in mind that the more successful a product is, the more feedback its developers receive. Users will point out both existing shortcomings and suggest improvements, including those entirely fantastic or irrelevant for the majority. You will need to learn how to deal with this influx of feedback and prioritize further product development.

In addition to creating a customer support system and processing customer feedback, you will need to pay attention to the following points:

- Continuously monitor any detected bugs or vulnerabilities and promptly release bug fixes and software updates.

- Provide firmware updates to improve your IoT devices’ functionality, security, and performance.

- Keep track of the security of your IoT products and customer data.

- Regularly monitor and optimize the performance of your IoT products.

A case study from 2Smart

Probably, the central insight we received after testing the MVP Propuskator is that our solution may be of interest not only to the B2B audience. We have found that access controllers are devices that private consumers can use. After the launch, we modified the solution so that the controllers could be operated without access control systems. To do this, we changed the firmware so that the device could connect to our IoT platform, 2Smart Cloud, and users could use a free mobile application to control access without registering in any deployed access control system.

Effectively implement your IoT solutions ideas with 2Smart

The 2Smart team has experience in independently bringing several IoT solutions to market and assisting other businesses in building IoT products. Our core competency is to provide a software solution for IoT developers, which includes a web application for developers, a business platform web application, and a mobile application for end users of devices.

If we talk about the niche of consumer devices, we have experience independently developing IoT smart lighting solutions. As part of this experiment, we went through the entire cycle of building an IoT device and bringing it to market. As a result, we are currently helping to create a similar solution for a business that specializes in smart lighting and has the necessary competencies for its successful sales and quality service.

Our experience in green energy includes collaboration with the MyBox brand, which develops and produces a range of charging stations for electric vehicles. We delivered a software solution to the MyBox team, which is a closed IoT platform with two web applications for device developers and business management of the entire fleet of products launched on the market, including the ability to connect an unlimited number of partners and subsidiaries. MyBox also received a mobile application for end users and technical employees, a white-label instance of the 2Smart Cloud application, which determines its affordable cost for the client.

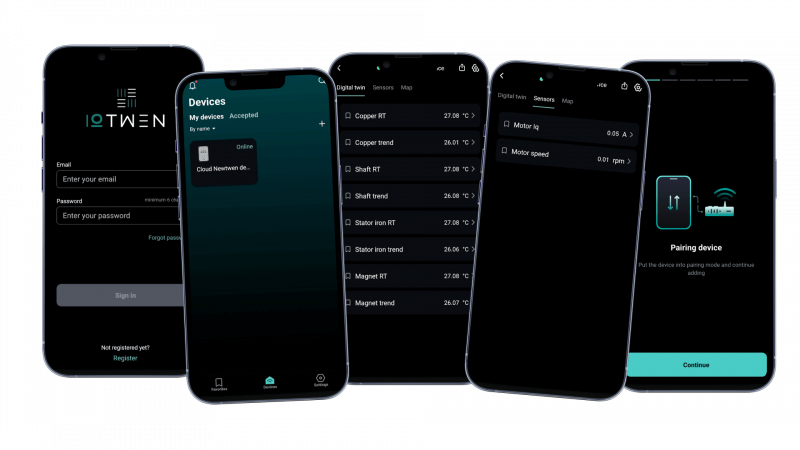

A white-label instance of the 2Smart Cloud mobile and web application was also received by Newtwen, which produces digital twins of physical devices.

Find out more about the 2Smart team’s experience in building IoT solutions in the Success Stories section of the company’s blog.

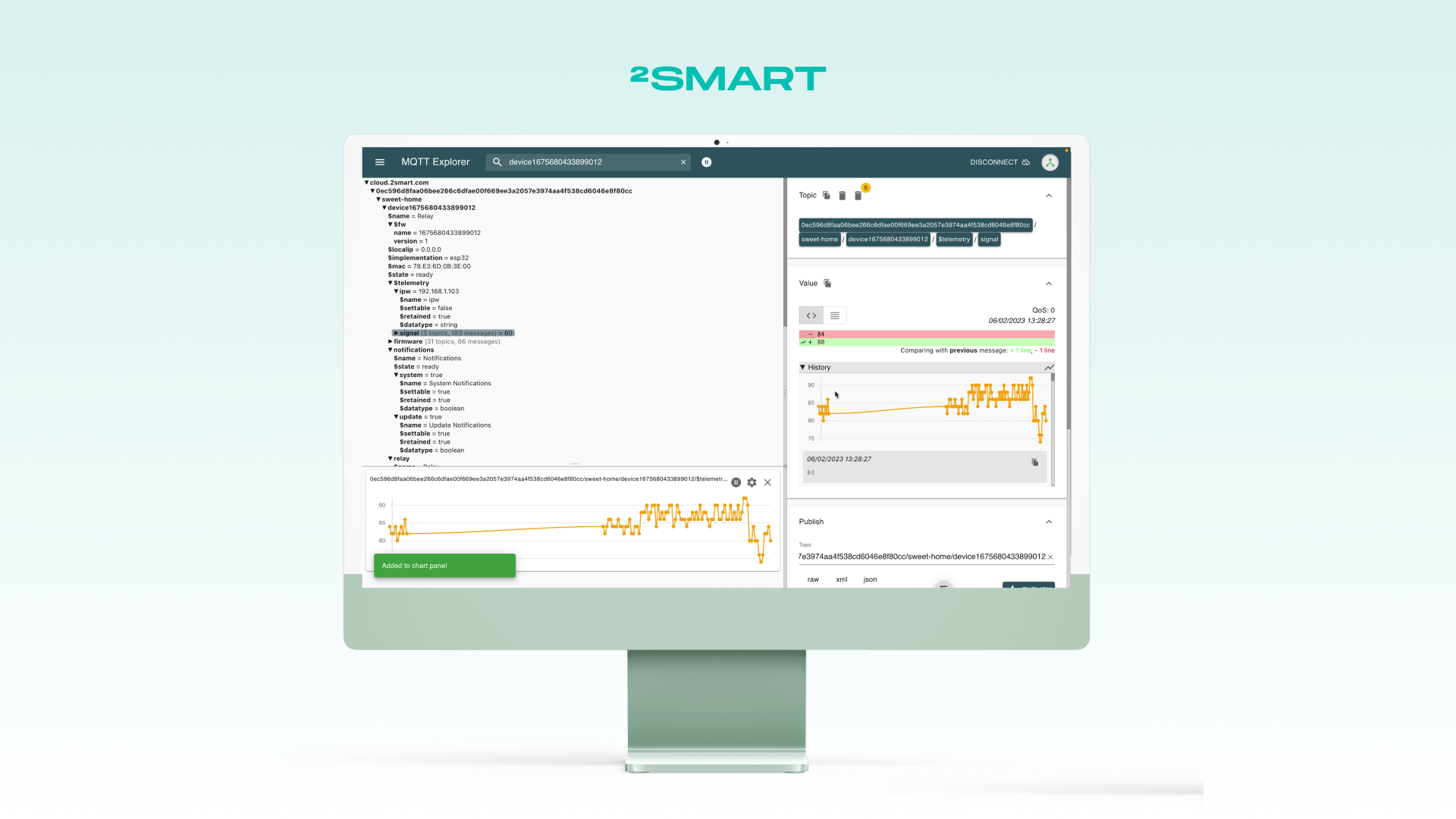

Use the capabilities of 2Smart Cloud at all stages, starting with the creation of Proof of Concept. Here you get:

- tools to facilitate the launch of PoC: IoT platform with a free connection to its MQTT broker for up to 20 of your devices, low-code tools for creating firmware, no-code mobile application builder with the ability to control the device from the browser;

- the ability to launch MVP in the B2B mode of the platform with its advanced capabilities for management, monitoring, and maintenance of a fleet of devices;

- a detailed knowledge base that will help you go through all the steps listed above to build an IoT solution using the 2Smart Cloud platform.

Don't forget to share this post!

Read Next

Let’s dive into your case

Share with us your business idea and expectations about the software or additional services.