Table of contents:

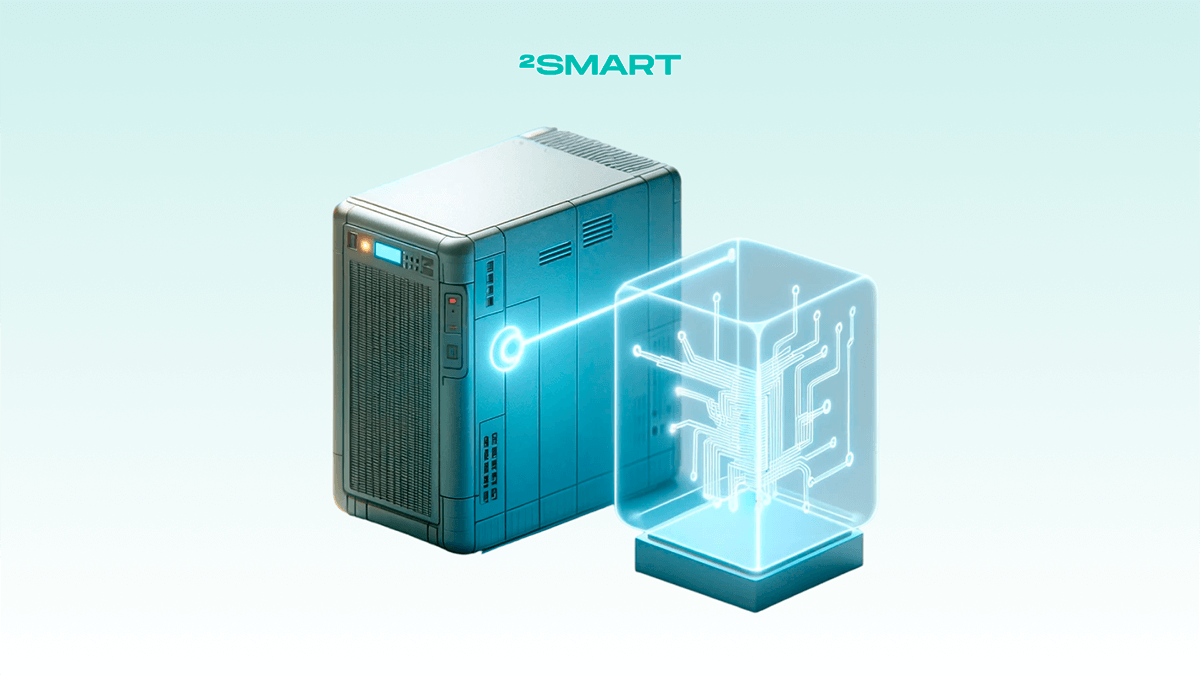

Digital twins simplify the process of testing and implementing new features and allow for the development and validation of a product before a physical prototype is even created. This approach saves time and resources, making the development process more flexible and efficient. In this article, the 2Smart team shares their experience using digital twins in developing the MyBox electric vehicle charging station network management platform. We will detail how this technology helps our team enhance quality and accelerate the introduction of innovations.

How Digital Twins Simplify Product Development and Testing

Before diving into the use of digital twins in development, let’s clarify what we’re talking about. Digital twins are virtual models of physical objects, processes, or systems created to simulate their real-world counterparts. Previously, we’ve covered in detail on our blog what digital twins are in IoT solutions and how they work.

When it comes to using digital twins in the daily routine of the 2Smart team, the MyBox project serves as a prime example. Here, we are developing a platform for managing a network of electric vehicle charging stations and implementing new features.

Let’s collaborate

We’re empower your business with our technology expertise

Charging stations are quite bulky devices that require specific handling when setting up and connecting the wiring. At the same time, we often work on functionalities that can only be tested through the interaction between the device and the platform. Thus, we see three options for organizing our work:

1. Provide each developer and tester with their own physical device.

- Drawbacks: This option is extremely difficult to implement due to the large size of the devices and the specific requirements for their connection. Additionally, as the team expands, finding “extra” devices becomes challenging.

- Advantages: Direct interaction with real devices ensures the highest accuracy in testing.

2. Test each functionality separately using APIs, scripts, auto-tests, and Swagger.

This approach is certainly valid, and we even use it for solving many tasks. However, it should be noted that it does not allow for comprehensive testing from the end user’s perspective.

- Drawbacks: Testing individual functionalities does not always reflect the real behavior of the system in a complex environment, which can lead to integration errors.

- Advantages: This method allows for the automation and acceleration of the testing process, especially in the early stages of development.

3. Provide developers and testers with a digital twin of the device duplicating the functionality of a real charging station.

- Drawbacks: Creating a digital twin requires initial effort and resources.

- Advantages: This option offers the most balanced approach:

- Digital twins simplify the learning process of the project and functionalities, especially for new employees undergoing onboarding.

- They streamline the process of “generating” data on the platform. This is particularly convenient for developers and testers who need to refine/test existing functionality they were not initially involved in.

- It allows easy modification and addition of new functionality.

- It enables testing of new platform functionalities before firmware integration.

- Test results are more reliable than using APIs. Practice shows that some backend tasks can be tested via APIs, but they may not work on the frontend. If testing on the digital twin is successful, it practically guarantees trouble-free implementation of this functionality on a real physical device.

- It allows work on new product functionality even before the real device is developed. To avoid relying solely on automated tests, we create a virtual device that emulates the real one, to save time and comprehensively test its functionality.

It is clear that the third option provides the greatest flexibility and efficiency. That is why our team chose to use digital twins for developing and testing the MyBox platform.

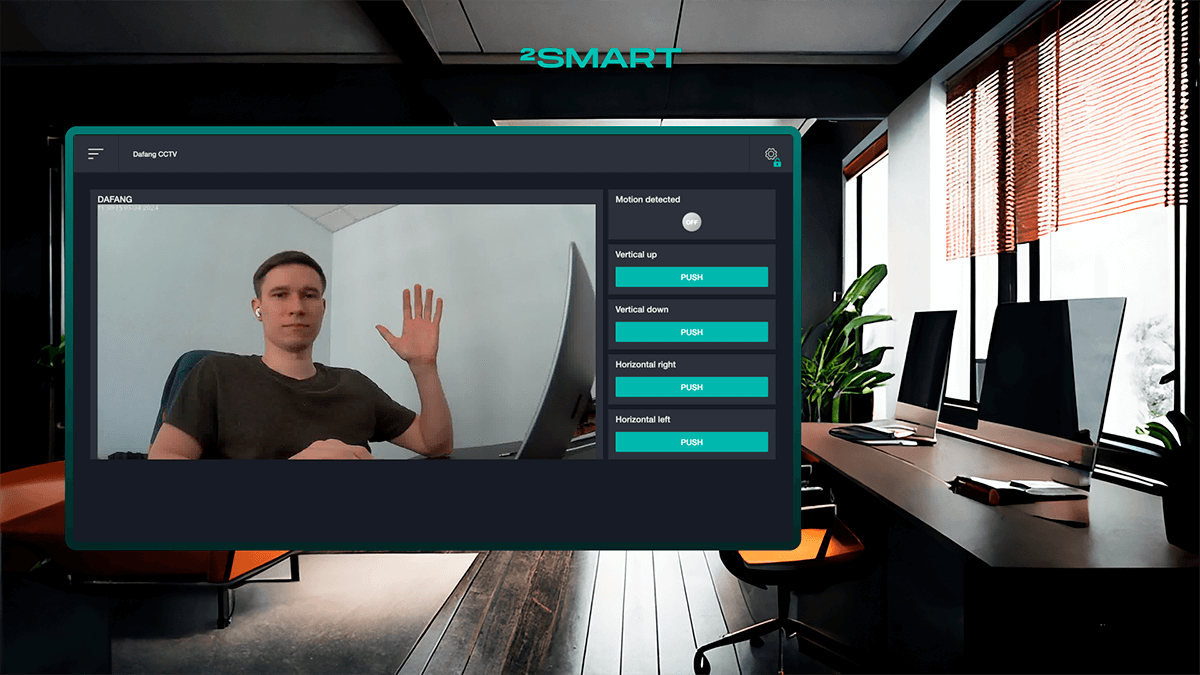

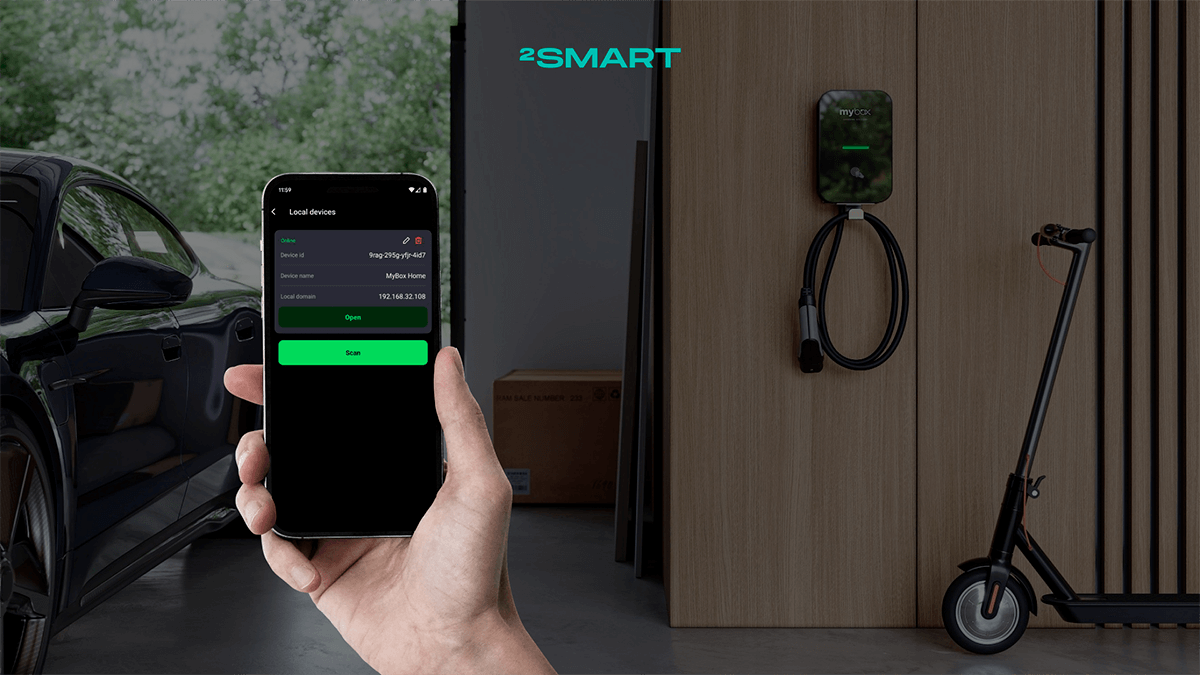

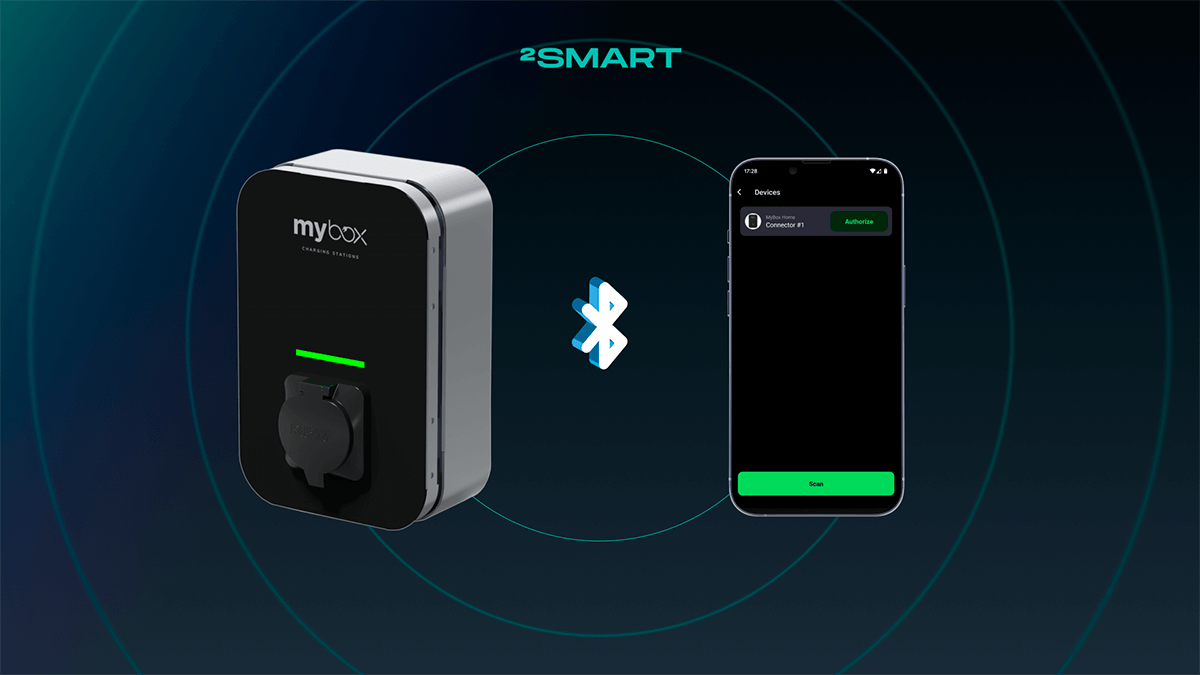

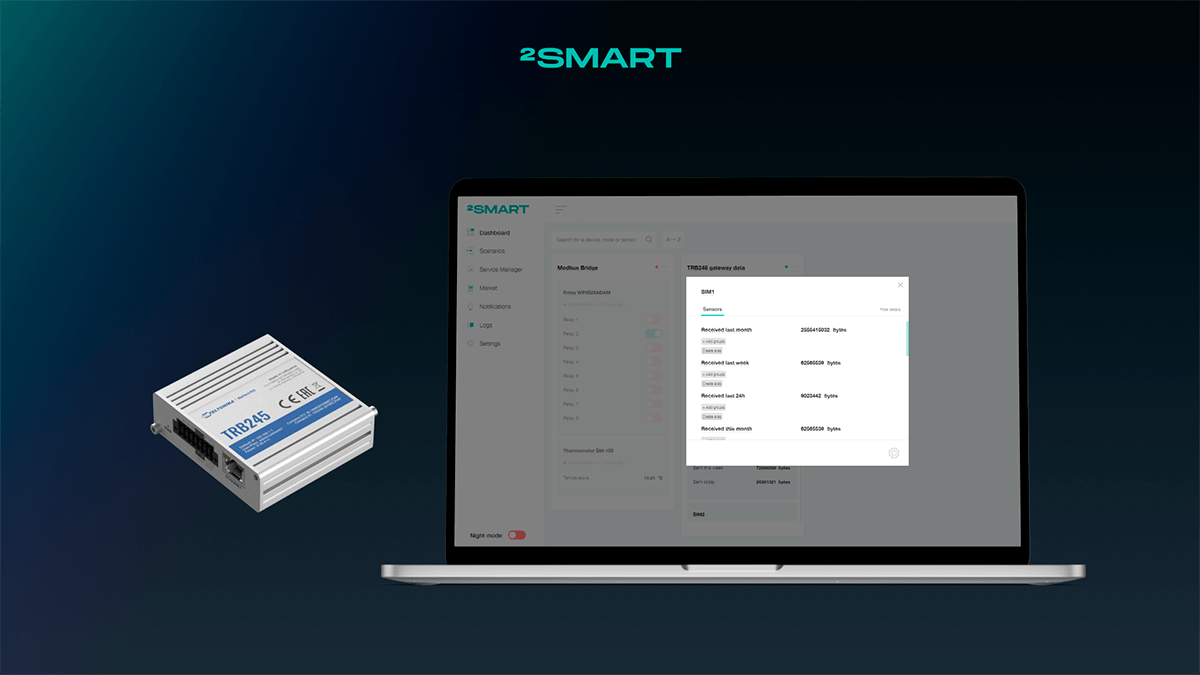

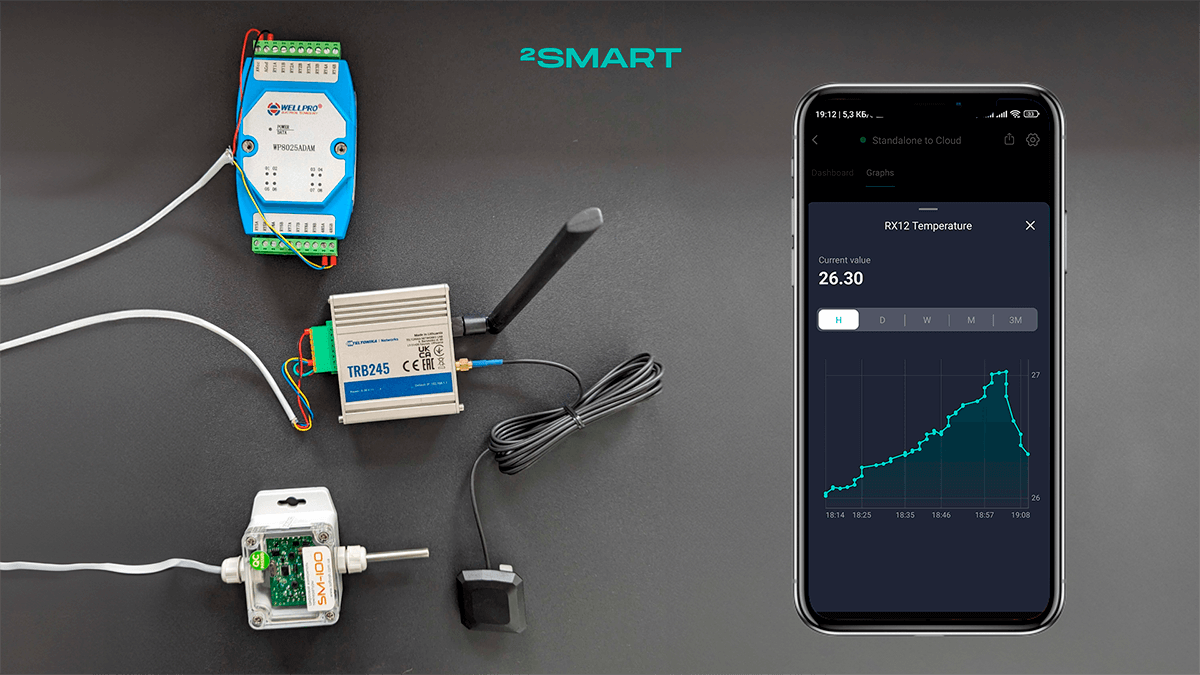

Below is a side-by-side comparison of how the digital twin and the real device appear in the mobile application and platform.

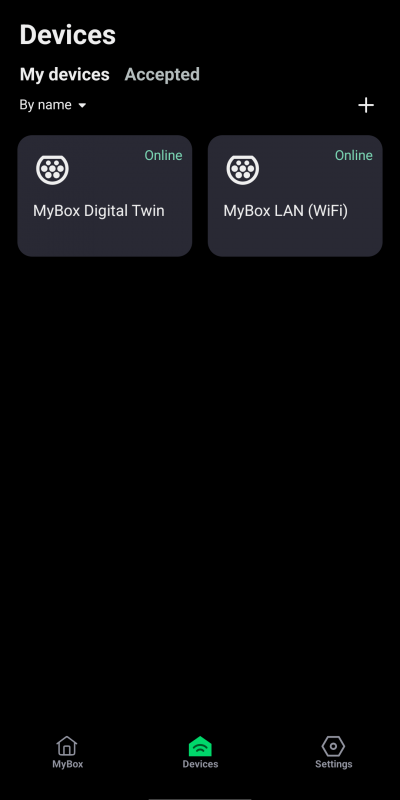

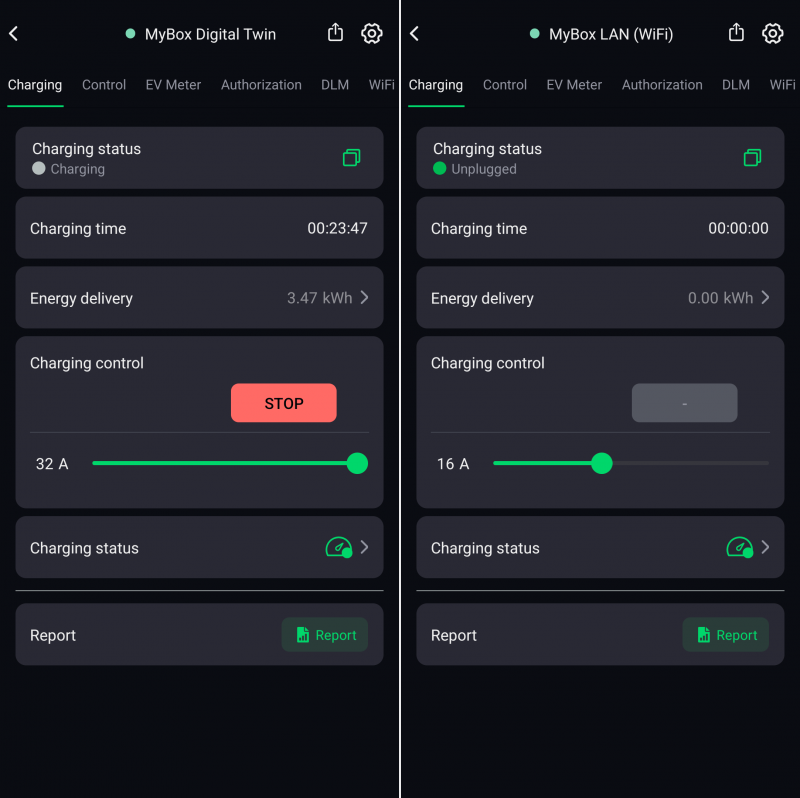

Here are screenshots of the mobile app, paired with both the real charging station – MyBox LAN, and its digital twin:

Here, you can see that the app layout for the real and virtual devices is the same. However, the digital twin is in charging status, so the sensor values differ:

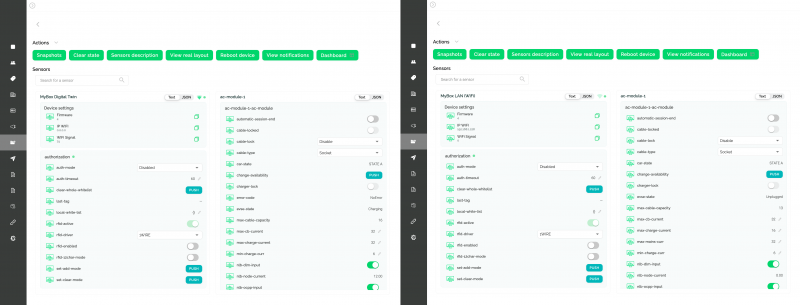

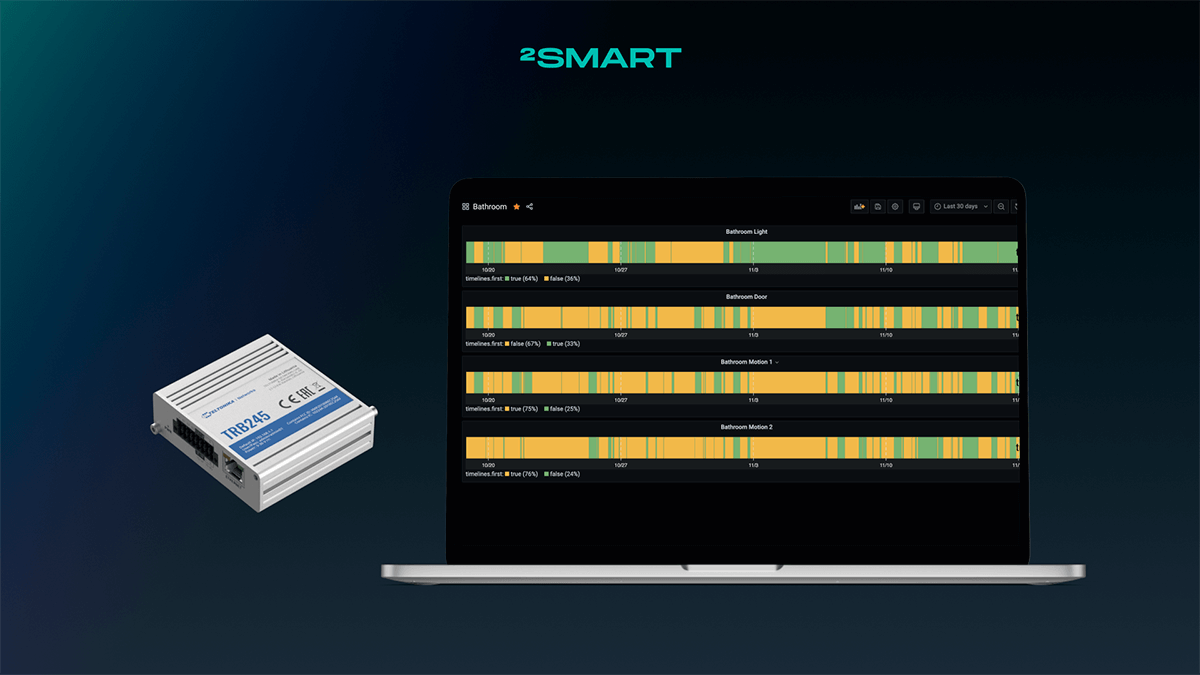

And here are the dashboards (left – digital twin, right – real charging station) when both devices are in charging mode:

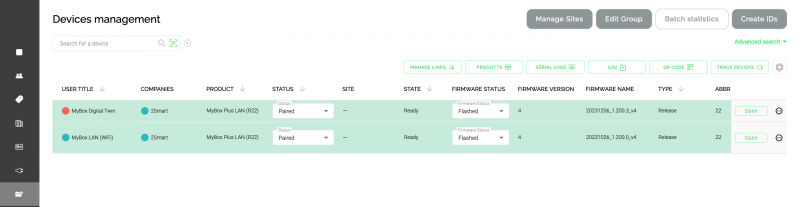

Here are screenshots taken from the admin panel of the platform for device management. The real device and its digital replica are displayed as instances of the same product, “MyBox Plus LAN (R22)”:

Here, you can see that both devices have the same set of sensors, and each transmits its own values:

Digital Twins in Product Testing: A Real-World Example

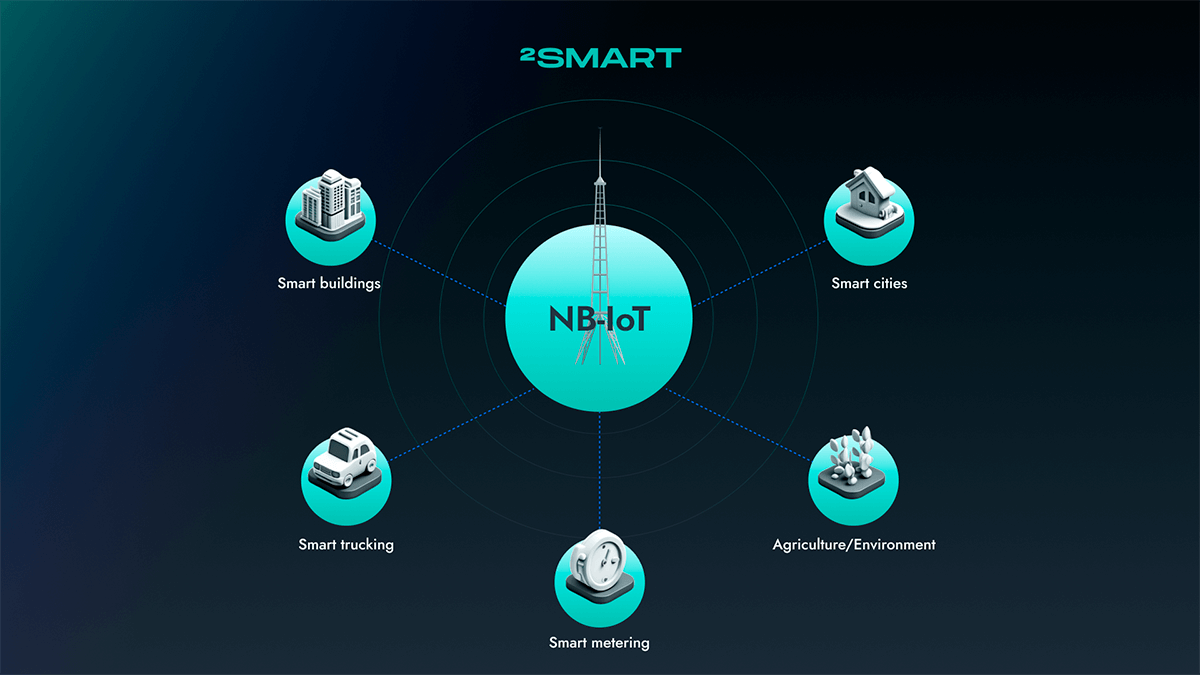

When discussing specific functionalities where digital twins have been particularly beneficial, it’s essential to mention the Dynamic Load Management (DLM) system, which distributes current among charging stations.

In our article about developing the MyBox platform, we detailed two DLM systems integrated into the platform. One system manages the load distribution among up to eight charging stations. The other, which we internally call Big DLM, balances up to 80 stations. Digital twins, integrated with the DLM API, were instrumental in developing Big DLM.

Obviously, we couldn’t set up 80 real charging stations to test DLM. This would have required significant investments in device delivery from the supplier, setting up a large testing facility, and connecting all these stations to the power grid. Digital twin technology eliminated these issues, allowing us to simulate and test without being limited by the number of devices connected to the system.

After refining the Big DLM functionality, the charging station manufacturer tested it on dozens of real devices in their testing environment and confirmed its functionality and safety.

Conclusion

Digital twins have radically transformed our approach to product development and testing. Using virtual models of charging stations has significantly accelerated the implementation of new features, reduced testing costs, and improved the quality of the final product. This technology has not only simplified the integration and debugging of systems but also enabled comprehensive testing in conditions that closely mimic real-world scenarios.

The MyBox project demonstrated that digital twins could be successfully applied to the development and testing of complex systems, such as a network of electric vehicle charging stations. The benefits they offer are especially noticeable in a growing team environment with the need for rapid innovation deployment.

In the future, we plan to continue using and advancing digital twin technology to further optimize our development and testing processes. This will enable us to stay at the forefront of technological progress and provide our clients with the most modern and reliable IoT solutions.

The experience of the 2Smart team shows that digital twins are becoming an essential tool for modern developers, opening new horizons for innovation and efficiency in production processes.

Let’s collaborate

We’re empower your business with our technology expertise

FAQ

What is a Digital Twin?

A digital twin is a virtual model of a physical object, process, or system created to simulate and analyze its real-world behavior. These models enable real-time monitoring and management of devices, as well as testing and optimization of their functionality.

How are Digital Twins Used in the Daily Work of the 2Smart Team?

The MyBox case is a prime example, where digital twins are used for developing and testing the platform that manages a network of electric vehicle charging stations. They allow us to simulate the real behavior of the stations, test new functionalities, and conduct comprehensive testing without the need for physical devices.

What Advantages Do Digital Twins Offer?

Digital twins accelerate the development process, reduce testing costs, improve the quality of the final product, and allow for more precise and reliable functionality testing. They also simplify the onboarding of new employees and enable work on functionalities before the physical device is created.

What Challenges Can Arise When Implementing Digital Twins?

Creating a digital twin requires initial effort and resources for development and setup. This can include writing code, modeling device behavior, and integrating with existing systems.

Can Digital Twins Be Used for All Types of Devices?

Digital twins are most effective for complex systems and devices that require comprehensive testing and monitoring. However, they can be useful for a wide range of devices and processes if their behavior can be accurately modeled.

How Do Digital Twins Assist in Training New Employees?

Digital twins enable new employees to quickly familiarize themselves with the functionality and architecture of the system by conducting tests and experiments in a virtual environment. This eases the onboarding process and speeds up their adaptation to project work.

How Reliable Are the Results of Testing on Digital Twins?

Testing on digital twins provides a high degree of reliability since they simulate the behavior of real devices. Successful testing on a digital twin practically guarantees smooth functionality deployment on the physical device.

What Are 2Smart Team’s Plans for the Future Use of Digital Twins?

The 2Smart team plans to continue using and advancing digital twin technology to optimize development and testing processes. This will allow us to offer our clients the most modern and reliable IoT solutions and stay at the forefront of technological progress.

Don't forget to share this post!

Read Next

Let’s dive into your case

Share with us your business idea and expectations about the software or additional services.